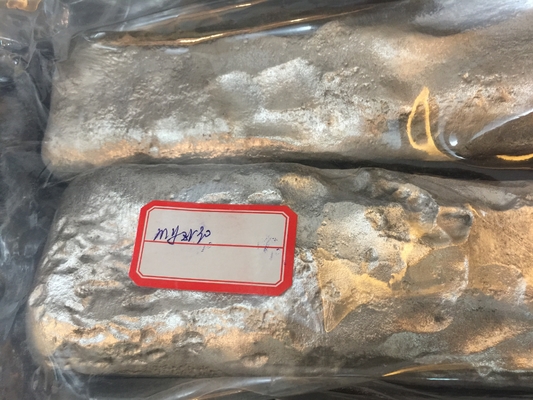

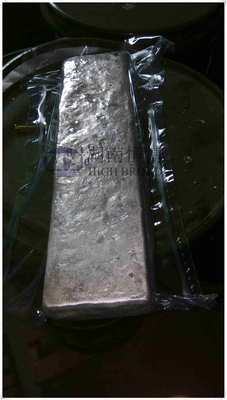

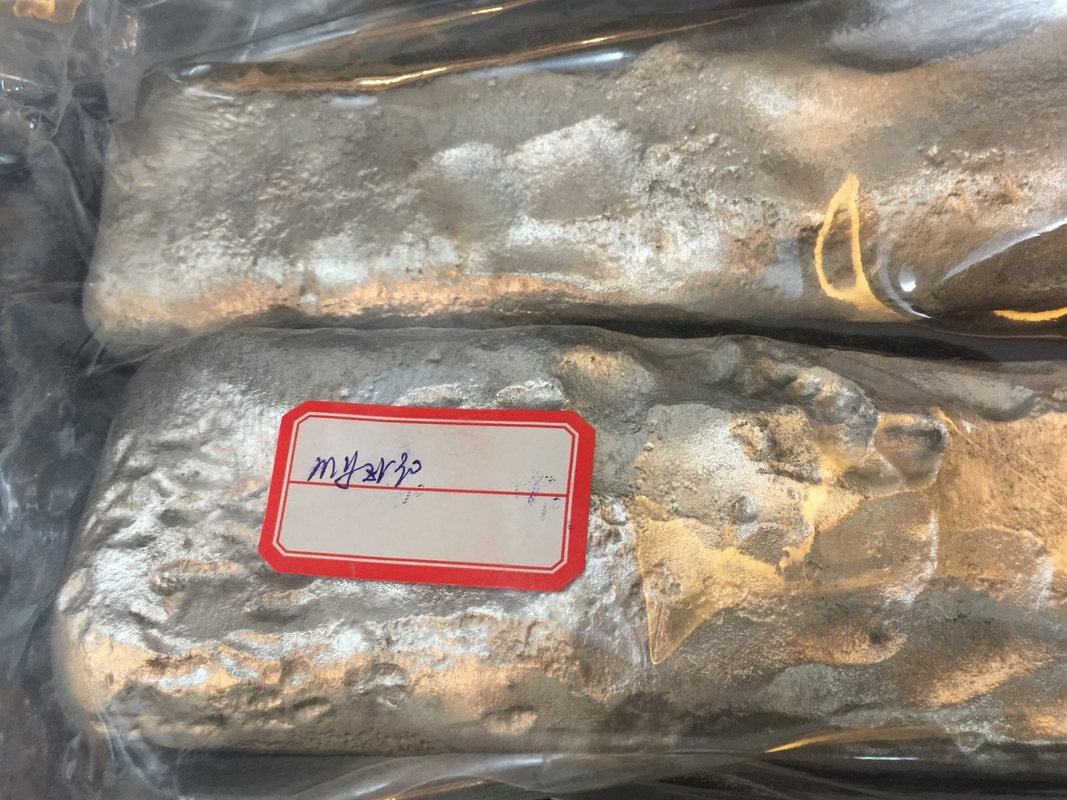

MgZr 10% 15% 20% 25% 30% 35% alloy ingot master alloy magnesium zirconium MgZr30 for grain refine magnesium smelting

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad/OEM |

| Certification: | ISO |

| Model Number: | MgZr30 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 kg |

|---|---|

| Price: | negotiable |

| Packaging Details: | In Vacuum plastic bag and then in steel drums |

| Delivery Time: | 1000 kgs: 2 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 500mt/month |

|

Detail Information |

|||

| Application: | Refine The Grain And Restrain The Growth Of Grain In Mg Alloy | Keywords: | MgZr |

|---|---|---|---|

| Chemical Composition: | Zr;Fe;Si;Cu;AI;Ni;Mn;Mg | Commodity: | MgY Alloy Ingot |

| Shape: | Magnesium Master Alloy With Rare Earth | Usage: | Refine Grain,improve Magnesium Product Physical Properties |

| Belongs: | Magnesium Master Alloy With Rare Earth | ||

| High Light: | magnesium sacrificial anode,magnesium aluminum alloy |

||

Product Description

Commodity : MgZr alloy magnesium zirconium

Chemical content: Zr 25 , Zr 30%

Application:

1. Refine the grain and restrain the growth of grain in Mg alloy

2. insoluble with Al,Fe,Si.

3. Add temperature : 820℃±50℃.

| Model NO. | Zr | Fe | Si | Cu | AI | Ni | Mn | Mg |

| ≥ | ≤ | Remainder | ||||||

| MgZr25 | 25 | 0.35 | 0.005 | 0.002 | 0.002 | 0.001 | 0.001 | |

| MgZr30 | 30 | 0.35 | 0.005 | 0.002 | 0.002 | 0.001 | 0.001 |

|

![]()

We also have other series of magnesium master alloys , such as MgY,MgLa,MgGd,MgNd etc. If you have interests, pls contact me.

Magnesium-zirconium casting alloy [1] Casting forming alloy based on magnesium and adding elemental zirconium. There are magnesium-zinc-chromium series, magnesium rare earth Hao series, magnesium billion (qin) complex series and other varieties. Density i.75-i.85g/rm'} melting range 445-55U}. Modulus of elasticity 44CiE'a tensile strength 15 (3-35UI4iPa o hardness (H13) SUU-$UUMPa, coefficient of thermal expansion (26.5-28.5) x 1U-"/ K. Elongation rate of 1%-1%. Has excellent cutting Performance, a smooth surface can be obtained without grinding and polishing. It is produced by the method of increasing the risk of smelting sand casting. It is used to manufacture aero engine accessory casings, fuel system parts, etc.

*What is Master alloy?

1.Grain Refiners

Control the structure and dispersion of individual crystals in metals

Improved mechanical strength and soundness of the casting

2.Modifiers

Change micro-structural properties of metal

Increase strength, toughness, ductility, and resultant machinability.

3.Hardeners

Change composition of metal alloys

*I don’t know how to use your products ?

Our professional technical engineer will provide detailed guidance to you.

* I should choose which product ?

Tell us your target material performance, we will provide accordingly master alloy or design a new type alloy especially for you !

*I have alloying production difficulties !

Do not worry ! We will provide professional technical solution to help you overcome problems!

![]()

![]()

1. Mg master alloys:

MgY25/30, MgMn3/5/10 , MgCa15/20, MgCe20/25/30, MgNd20/25/30, MgSc2/5/10/30, MgGd20/25/30,MgSr10/20, MgLa20/25/30,MgZr25/30,MgEr20,MgAl50/68,MgCu15/30,

MgLi10,MgSi3 ,MgDy20/30,MgSm20, MgPr20,MgHo10, MgCd20,MgBa10 ,MgZn30,MgLaCe,NiMg etc.

ZK60, ZM2,ZM3,ZM6,ZM21,ZM31,WE43,WE57,WE94,MnE21 ,WZ73,Dissolving magnesium etc.

For Magnesium alloys, we have strong technical team to supply customized alloy according to customers demand.

2.Al master alloys:

AlCu,AlNd,AlGd,AlY,AlZn,AlEr,AlLa,AlCe,AlSc,AlScZr,AlCo,AlCr,AlMo,AlNb,AlLi,AlAg,AlYb,AlHf,AlDy,AlRe10 ,AlTiC ,AlIn, AlSn etc.

3. Cu master alloys:

CuBe,CuTi,CuZr,CuCr ,CuP ,CuAl,CuMg ,CuCd , CuSn,CuCa,CuCe,CuFe,CuSi,CuTe,CuV,CuAg,CuLi,CuMn,CuCo,CuAs,CuSb,CuB, etc.

4. Zn master alloys:

ZnLi2, ZnLiCu, ZnMn10,ZnY3, ZnLa,ZnRe etc.

![]()