ASTM Standard Magnesium Extrusion for High Magnesium Wires

Product Details:

| Place of Origin: | Hunan China |

| Brand Name: | HB |

| Model Number: | MG |

|

Detail Information |

|||

| Produce: | Cast | Content: | Magnesium Alloy AZ61 TUBE |

|---|---|---|---|

| Application: | Aircraft Parts | Standard: | ASTM Magnesium Alloy Extrusions |

| Magnesium Alloy Plate: | Stainless Steel Sheet | Chemical Composition: | Magnesium Alloy |

| Surface Finish: | Extrusion | Type: | AZ31B, ME20M |

| High Light: | ASTM Standard Magnesium Extrusions,Aircraft Parts Magnesium Alloy Extrusions,Wires Magnesium Extrusions |

||

Product Description

Product Description:

Welcome to our product overview for Magnesium Extrusion, a top-of-the-line magnesium alloy extrusion product designed specifically for the aerospace industry. Our extruded components are made to meet the high standards of ASTM and are perfect for a variety of applications, including aircraft parts.

Our Magnesium Extrusion products are manufactured in accordance with the standards set by ASTM, ensuring the highest quality and reliability. Our extrusions are made from high-grade magnesium alloy, known for its exceptional strength and durability.

With a melting point of 650°C, our Magnesium Extrusion products are able to withstand extreme temperatures, making them ideal for use in aerospace applications. Our extruded components are designed to perform under the most challenging conditions, ensuring the safety and reliability of your aircraft.

The use of stainless steel sheet as the base material for our Magnesium Alloy Plate allows for a lightweight yet strong product. This makes our extruded components perfect for reducing the overall weight of aircraft, resulting in improved fuel efficiency and performance.

Magnesium is known for its exceptional durability and corrosion resistance, making it an ideal material for use in aircraft parts. Our Magnesium Extrusion products are designed to withstand harsh environments and frequent use, ensuring a long lifespan and minimal maintenance.

One of the key advantages of our Magnesium Extrusion products is their high strength-to-weight ratio. This means that our extruded components are able to provide exceptional strength and performance while keeping overall weight to a minimum.

Our Magnesium Extrusion products are manufactured using precision techniques, ensuring the highest level of accuracy and quality. This allows for a perfect fit and seamless integration into your aircraft, providing optimal performance and reliability.

In conclusion, our Magnesium Extrusion products are the perfect choice for any aerospace application. With their high-quality standard, high melting point, lightweight and strong design, durability, high strength-to-weight ratio, and precision manufacturing, they are the top choice for aircraft parts. Choose Magnesium Extrusion for your aerospace needs and experience the best in quality and performance.

Features:

- Product Name: Magnesium Extrusion

- Shape: Extrusion

- Application: Aircraft Parts

- Product: Magnesium Wires

- Surface Finish: Extrusion

- Chemical Composition: Magnesium Alloy

- Extruded Magnesium Alloy Products

- Magnesium Extrusion Profiles

- Extruded Magnesium Alloy Products for Aircraft Parts

- Magnesium Alloy Wires

- Extruded Surface Finish

Technical Parameters:

| Product Name | Magnesium Extrusion |

|---|---|

| Content | Magnesium Alloy AZ61 TUBE |

| Chemical Composition | Magnesium Alloy |

| Thickness | 1MM, 1.5MM, 2MM, 3MM, 5MM, 10MM, 50MM |

| Type | AZ31B, ME20M |

| Melting Point | 650°C |

| Magnesium Alloy Plate | Stainless Steel Sheet |

| Standard | ASTM Magnesium Alloy Extrusions |

| Product | Magnesium Wires |

| Application | Aircraft Parts |

| Sacificial Anode Standard | Mg Mn Alloy M1C |

Applications:

Magnesium Extrusion, also known as MG Extrusion, is a type of extruded magnesium alloy products with the brand name "HB". It is produced in Hunan, China and has a surface finish of extrusion. With its high quality and excellent properties, Magnesium Extrusion has become a popular choice in many industries.

As a lightweight and high strength material, Magnesium Extrusion offers a wide range of applications in different industries. It is widely used in the automotive industry, aerospace industry, sports equipment, medical industry, and more.

- Brand Name: HB

- Model Number: MG

- Place of Origin: Hunan, China

- Surface Finish: Extrusion

- Sacrificial Anode Standard: Mg Mn Alloy M1C

- Magnesium Alloy Plate: Stainless Steel Sheet

- Standard: ASTM Magnesium Alloy Extrusions

- Density: 1.74g/cm³

Magnesium Extrusion is widely used in various industries due to its excellent properties. Here are some of the common applications:

In the automotive industry, Magnesium Extrusion is commonly used to produce lightweight and high-strength components such as engine parts, transmission parts, and wheels. Its lightweight property helps to reduce the overall weight of the vehicle, resulting in better fuel efficiency and performance. Its high strength also makes it suitable for use in safety components.

Magnesium Extrusion is also widely used in the aerospace industry due to its lightweight and high strength properties. It is an ideal material for producing aircraft components such as landing gear, engine parts, and structural components. Its high corrosion resistance also makes it suitable for use in harsh environments.

Many sports equipment manufacturers are now using Magnesium Extrusion to produce lightweight and high strength equipment. It is commonly used in the production of golf clubs, tennis rackets, and bicycles. Its lightweight property helps to improve performance and reduce fatigue for athletes.

In the medical industry, Magnesium Extrusion is used to produce lightweight and biocompatible implants such as bone screws and plates. Its high strength and corrosion resistance make it an ideal material for use in medical applications.

These are just some of the many possible applications of Magnesium Extrusion. With its excellent properties and wide range of uses, it has become an essential material in various industries.

Source: HB Magnesium Extrusion Official Website

© All rights reserved.

Customization:

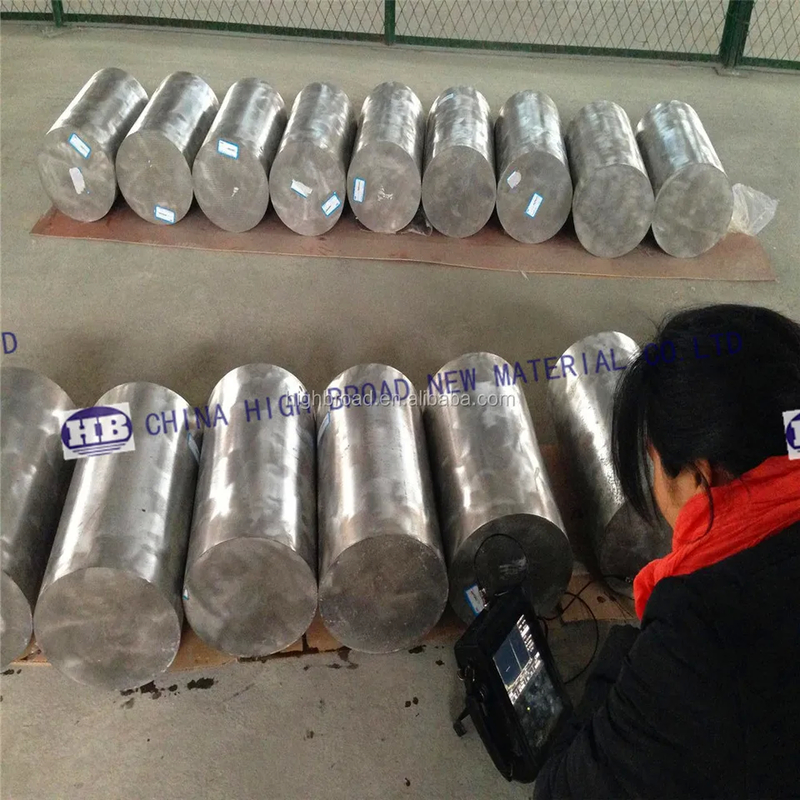

At HB, we specialize in providing customized services for magnesium extrusion products and components. Our MG model offers precise tolerance and tailored solutions to meet your specific requirements. With our expertise in magnesium extrusion, we ensure high quality and cost-effective solutions for our customers.

Our magnesium extrusion products are proudly made in Hunan China, utilizing cast production for superior results. This allows us to offer a wide range of shapes and sizes for our customers' needs.

Our content includes the use of Magnesium Alloy AZ61 TUBE, known for its lightweight and high strength properties. This makes it an ideal choice for various applications, especially in the aerospace industry.

Our magnesium extrusion products have a density of 1.74g/cm³, ensuring optimal performance for your specific application. This allows for a lightweight and durable solution for your needs.

We follow the sacificial anode standard of Mg Mn Alloy M1C, providing excellent corrosion resistance for our magnesium extrusion products. This makes them suitable for use in harsh environments and extended lifespans for your equipment.

Our magnesium extrusion products are commonly used in aircraft parts, due to their lightweight and strong properties. This makes them a reliable choice for critical components in the aerospace industry.

Choose HB for your customized magnesium extrusion needs and experience the HB difference. Contact us today to learn more about our tailored solutions and how we can meet your specific requirements.

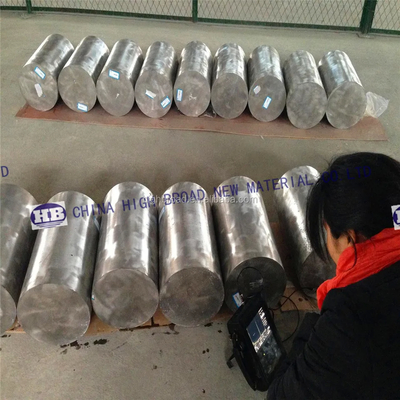

Packing and Shipping:

Our Magnesium Extrusion product is carefully packaged to ensure safe and secure delivery to our customers. Each extrusion is individually wrapped in protective material and then placed in a sturdy cardboard box. The box is sealed with high-quality tape to prevent any damage during transportation.

We offer both domestic and international shipping options for our Magnesium Extrusion product. For domestic shipping, we use trusted and reliable carriers such as UPS, FedEx, and DHL. For international shipping, we work with these carriers as well as other freight forwarders to ensure timely and efficient delivery.

Customers can also choose their preferred shipping method and carrier at the time of purchase. We strive to provide competitive shipping rates and expedited shipping options for urgent orders.

All shipments are tracked and customers will receive a tracking number to monitor the status of their order. We also offer shipping insurance for additional protection of our customers' orders.

Our packaging and shipping processes are constantly reviewed and improved to ensure the best possible experience for our customers. We welcome any feedback or suggestions for improvement.

FAQ:

- Q: What is the brand name of this product?

- A: The brand name of this product is HB.

- Q: What is the model number of this product?

- A: The model number of this product is MG.

- Q: Where is this product made?

- A: This product is made in Hunan, China.

- Q: What is the main material used in this product?

- A: The main material used in this product is magnesium.

- Q: Can this product be customized to fit specific requirements?

- A: Yes, this product can be customized to fit specific requirements.