M1C Water Heater Magnesium Anode Rods Travel Trailer Camper Heat Tank Water Heater Anode

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM HIGH BROAD |

| Certification: | ASTM G-97, ISO, DNV , ROHS |

| Model Number: | OEM Custom-made high quality mg anode |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 Kilograms |

|---|---|

| Price: | negotiable |

| Packaging Details: | On pallet with steel bundles |

| Delivery Time: | 1 FCL:14 Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 300 Metric Ton/Metric Tons per Month |

|

Detail Information |

|||

| Name: | Solar Water Heater Parts Magnesium Anodes Rod For Hard Water | Material: | Typically M1C, Grade HP |

|---|---|---|---|

| Application: | Engine Solar Water Tank Oil Tank Storage Tank Condenser | Ability: | NPT BSP G GALVANIC STEEL Plug |

| Certificate: | ROHS Reach | ||

| High Light: | M1C High Potential Magnesium Anode Rod,Water Heater Magnesium Anode Rod |

||

Product Description

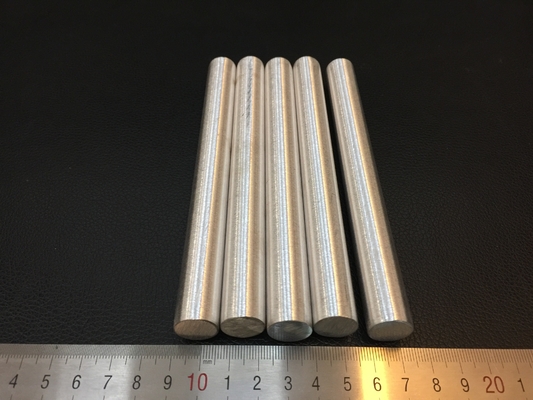

M1C High Potential Water Heater Magnesium Anode Rod Travel Trailer Camper Heat Tank Water Heater Anode

Introduction of anode rods for protection of water heater inner tanks. Volumetric electric water heaters are the most common and commonly used water heaters. The steel materials of the inner tank are divided into steel pottery coating, steel galvanized, stainless steel and so on. Many domestic water heater manufacturers use basically the above three types of inner tanks. The steel inner tank is exposed to a hot water environment of about 70 for a long time, and the inner wall will be severely corroded. The corrosion products have a certain impact on the water quality, resulting in the inner wall. The gall bladder wears the notification to waste. Professional foreign water heater manufacturers usually use sacrificial anode and cathodic protection to solve the problem of pinhole corrosion and penetration of the inner tank. This method is quite mature and commercialized. However, some domestic water heater manufacturers know little about the production and application of this anode rod alloy material. Therefore, the technical research of using cathodic protection to effectively control the corrosion of the inner tank wall urgently needs to be popularized. 1. Screening and evaluation of sacrificial anode materials Cathodic protection technology is used for the corrosion protection of the inner tank of electric water heaters, and the sacrificial anode method is usually adopted. The sacrificial anode method is to couple the metal to be protected with an active metal with a more negative potential. Because the two electrodes have different potentials, they form a galvanic cell, thereby generating a cathodic current that plays a role of cathodic protection, which has a higher potential than the protected metal. The negative active metal is the sacrificial anode (usually called magnesium alloy sacrificial anode rod in water heater applications). 1.1 The sacrificial anode materials widely used at present mainly include: zinc, zinc alloy, aluminum alloy, magnesium and magnesium alloy, etc. Among these anodes, magnesium and magnesium alloy anodes have the lowest potential, and have a large drive potential to iron. The open circuit potential is -1.6V to -1.7V, which is especially suitable for use in fresh water with high resistivity. In addition, magnesium is also necessary for the human body and has no toxic side effects to the human body. The disadvantage is that the self-corrosion effect is large, the efficiency is low (only about 50%, due to the hydrogen evolution on the electrode surface, the negative difference effect and the cause of the metal shedding), and the consumption is fast. Despite the shortcomings in the above-mentioned aspects, compared with other sacrificial anode alloys, magnesium alloy is still the preferred material for water heater anodes. The current efficiency of the zinc anode can reach 95%. In the water heater, zinc is usually used as a sacrificial anode in the form of zinc or electro-galvanized. However, the passivation performance of the zinc anode increases with the temperature, and the zinc electrode potential shifts positively, zinc-iron Electricity

![]()

![]()

Specification

| Alloy | AZ31B | Mg-Mn | Aluminum | |

|

Chemical Composition |

Aluminum | 2.50-3.50% | 0.01% Max | Balance |

| Manganese | 0.20-1.00% | 0.50-1.30% | - - | |

| Zinc | 0.60-1.40% | - - | 4.00-5.00% Max | |

| Calcium | 0.04% Max | - - | - - | |

| Silicon | 0.10% Max | - - | 0.25% Max | |

| Copper | 0.01% Max | 0.02% Max | - - | |

| Nickel | 0.001% Max | 0.001% Max | - - | |

| Fe | 0.005% Max | 0.03% Max | 0.25% Max | |

| Sn | -- | - - | 0.05-0.25% Max | |

| Other purity(each) | -- | 0.05% max | - - | |

| Total purity | 0.30% Max | 0.30% Max | 0.15% Max | |

| Remaining | Magnesium | Magnesium |

Dimension and Weight

| Diameter(inch) | Core eccentric(inch) | Core diameter(inch) | Straightness(inch/2 ft length) | Weight(lbs/inch) |

| Magnesium Extruded rod | ||||

| 0.0675-0.020 | 0.050 | 0.135 | 0.060 | 0.025 |

| 0.750-0.020 | 1/16 | 0.135 | 0.040 | 0.031 |

| 0.800-0.020 | 1/16 | 0.135 | 0.040 | 0.035 |

| 0.840-0.020 | 1/16 | 0.135 | 0.040 | 0.038 |

| 0.900-0.020 | 1/16 | 0.135 | 0.040 | 0.043 |

| 1.050-0.020 | 1/16 | 0.135 | 0.040 | 0.057 |

| 1.315-0.020 | 1/16 | 0.135 | 0.040 | 0.089 |

| Aluminum Extruded rod | ||||

| 0.576-0.020 | 0.050 | 0.135 | 0.060 | 0.038 |

| 0.750-0.020 | 1/16 | 0.135 | 0.050 |

0.048 |