TC Tungsten carbide B4C Boron Carbide Sandblasting Nozzles Spray Sand Nozzle Sandblasting

Product Details:

| Place of Origin: | China |

| Brand Name: | Sandblasting Nozzles |

| Certification: | ISO |

| Model Number: | Long Venturi Sandblast Nozzles |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20 PIECES |

|---|---|

| Price: | negotiable |

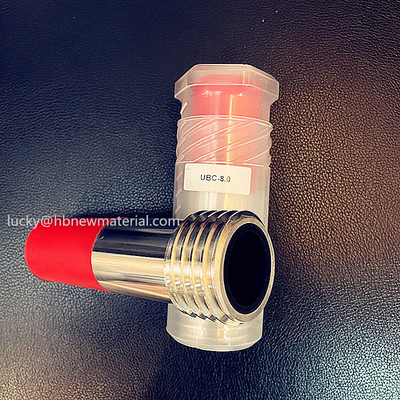

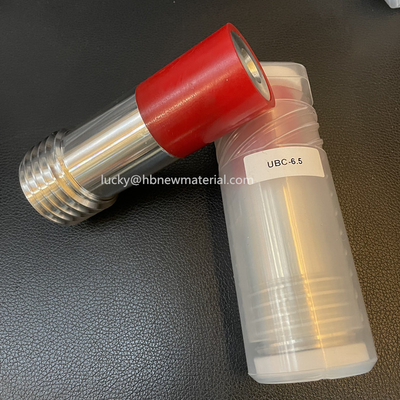

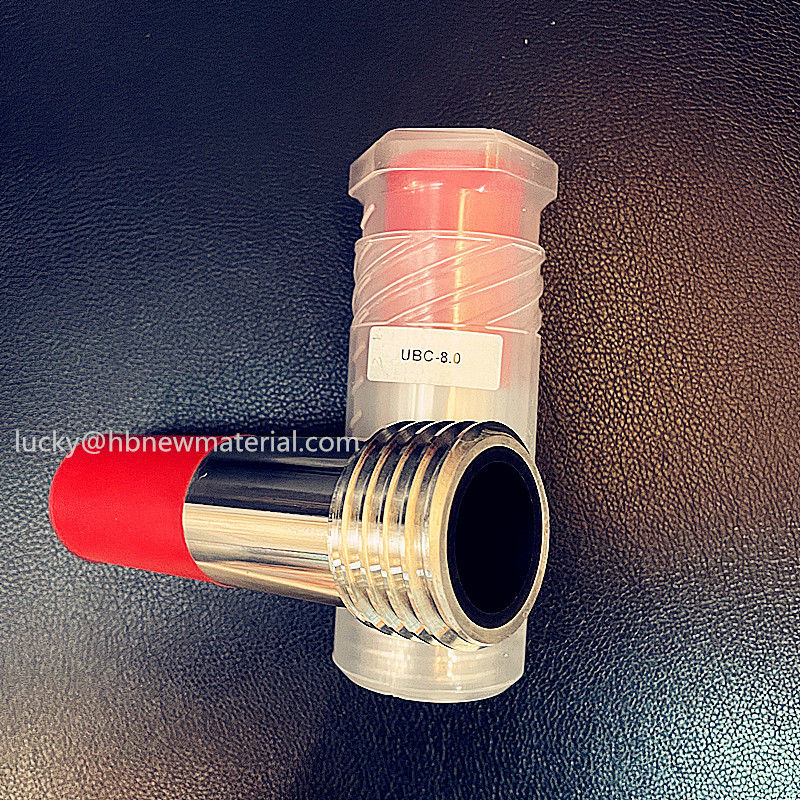

| Packaging Details: | each nozzle first into plastic tube then in export carton |

| Delivery Time: | 100pieces: 10 working days |

| Payment Terms: | Western Union, L/C, D/P, T/T, D/A, Western Union, MoneyGram |

| Supply Ability: | 100000 pieces each month |

|

Detail Information |

|||

| Sandblast Nozzle For Clean Equipment: | Sandblasting Spare Tool Parts Carbide Blasting Nozzles | Hotpress Nozzle: | Sandblast Nozzle For Clean Equipment |

|---|---|---|---|

| B4C Nozzle: | Boron Carbide Sandblasting Nozzle, Spray Sand Nozzle | Spray Sand Nozzle: | Sandblasting Spare Tool Parts Carbide Blasting Nozzles |

| B4C: | Sandblasting Nozzles | Density: | ≥2.48g/cm3 |

| Nozzle Material: | Boron Carbide+aluminum Jacket | Material Nozzle: | Tungsten Carbide+aluminum Jacket |

| High Light: | sand blast nozzle,sandblaster nozzle |

||

Product Description

The sandblasting venturi nozzles are made from boron carbide and aluminum jacket. The boron carbide is in very high hardness, excellent wear resistance and the boron carbide won’t react with acid-base. High/low temperature resistance, high pressure resistant, density≥2.46g/cm3,micro hardness≥3500kgf/mm2, TRS≥400Mpa, melting point is 2450℃. With above performance, now many customers choose the boron carbide material used especially in light armor, reactor neutron absorber. In addition, compared with the diamond and cubic boron nitride, boron carbide is easier to manufacture with low cost, and therefore is is more widely used in sandblasting, grinding, drilling and others.

The density also can be made to ≥2.48g/cm3

our products

1) made from 100% virgin raw material;

2) produced with advanced equipments;

3) all products go through in-process and final inspection;

4) free professional technical service online.

our service

1) OEM & ODM are welcomed;

2) customized design is available;

3) reply your enquiry in 24 working hours;

4) experienced staffs answer all your questions in fluent English;

5) best after-sale service.

our company

China Hunan High Broad New Material Co.,Ltd. established in Changsha City, Hunan Province,capital of Hunan province. We own a factory specialized in cemented carbide and related tools, we also do many other OEM products as request from customers. As a professional manufacturer, we are equipped with advanced equipments and specialized persons, especially have rich experience in making customized products. Over 20 years, we have been committing to "High Quality, Best Price, Sincere Service" as soul of our factory.

Our factory have a whole set of machines, including sieve shaker, press machine, sintering furnace, dryer, grinder, lathe, milling machine, cnc wire-cut machine, radial drilling machine, spark erosion drilling machine, etc. We also gathered the professional staff members in the area of designing, producing and sales and our workers are well trained and experienced.

| Material | Length(mm) | OD(mm) | ID(mm) |

| Boron carbide | 35 | 20 | 8,10 |

| Boron carbide | 60 | 20 | 6,8,10 |

| Boron carbide | 55 | 20 | 8,10 |

| Boron carbide | 55 | 20 | 6 |

| Boron carbide | 45 | 20 | 6 |

| Boron carbide | 80 | 20 | 6,8,10 |

| Boron carbide | 45 | 20 | 8,10 |

| Boron carbide | 45 | 15 | 8,10 |

| Boron carbide | 82 | 21 | 6,8,10 |

| Boron carbide | 55 | 15 | 6,8 |

Common type venturi nozzle with aluminum jacket:

Thread: 1-1/4”, 11-1/2N.P.S.M.

2”, 4-1/2U.N.C.

| Model | Bore Dia | Length |

| HB-B4C04 | 4.8mm | 110mm |

| HB-B4C06 | 6.4mm | 130mm |

| HB-B4C08 | 7.9mm | 150mm |

| HB-B4C09 | 9.5mm | 170mm |

| HB-B4C11 | 11.1mm | 200mm |

| HB-B4C12 | 12.7mm | 210mm |

![]()

we also can customized for you according to your drawing!