Venturi Boron Carbide Blast Nozzle Sandblaster Parts Nozzle High Temperature Resistance

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | HIGH BROAD |

| Certification: | ISO |

| Model Number: | Boron carbide nozzle |

Payment & Shipping Terms:

| Minimum Order Quantity: | 20 pieces |

|---|---|

| Price: | negotiable |

| Packaging Details: | Nozzle first into plastic tube then in export carton |

| Delivery Time: | 5-20 work day |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100000 pcs each years |

|

Detail Information |

|||

| Material: | Boron Carbide Nozzle | Type: | Sandblasting Nozzle |

|---|---|---|---|

| Boron Carbide Nozzle: | Straight Bore And Venturi Bore High Temperature Resistance Boron Carbide Nozzle | Usage: | Boron Carbide B4C Sandblasting Gun Nozzle For Sandblasting Cabinet |

| Sandblasting: | Boron Carbide Nozzle For Sandblaster | Hot Products: | Nozzle Insert |

| Popular Type: | Venturi Nozzle | ||

| High Light: | ceramic sandblast nozzle,carbide sandblast nozzle |

||

Product Description

Boron Carbide B4c Sandblasting Gun Nozzle for Sandblasting Cabinet

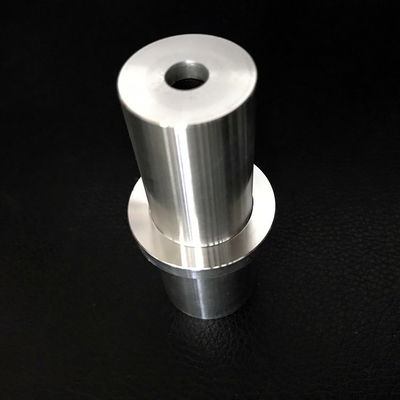

Venturi Boron Carbide Blast Nozzle , Sandblaster Parts Nozzle High Temperature Resistance

Boron carbide nozzle straight bore and venturi bore high temperature resistance boron carbide nozzle with aluminium jacket

Gas dynamic of venturi nozzle is better than straight-hole nozzle, the vortex is improved or ceased to exist, greatly reduced the pressure loss in the same pressure conditions. Abrasive exports increased to more than double the speed, efficiency than the straight-hole nozzle to increase 15% -40%, 20% lower abrasive consumption.

| Model | Bore Dia | Length | thread |

| HB-B4C06 | 6.4mm | 130mm |

fine thread or coarse thread

|

| HB-B4C08 | 7.9mm | 150mm | fine thread or coarse thread |

| HB-B4C09 | 9.5mm | 170mm | fine thread or coarse thread |

| HB-B4C11 | 11.1mm | 200mm | fine thread or coarse thread |

| HB-B4C12 | 12.7mm | 210mm | fine thread or coarse thread |

![]()

Abrasive blasting nozzles

Sand Blasting Boron Carbide Nozzle

High hardness, Low density, High temperature resistant, Excellent wear and anti-corrosion.

Sand Blasting Boron Carbide Nozzle

This kind of nozzle is made from boron carbide by hot pressing with straight bore and venturi bore type. Because of its hardness, low density, high temperature resistance, excellent wear and anti-corrosion, Boron Carbide Nozzle has been widely used in sandblasting and shot peening equipments, offering a longest life with optimum air and abrasive use.

Products application:

Equipped on the blasting machine and used as sand blasting.

Can be used to remove rust, water cutting etc.

![]()

![]()

Product features:

material : boron carbide

Density:>=2.48/cm3 .Microhardness>=3500kgf/mm2. Flexural strength>=400MPa

Melting point :2450℃

Advantages

1. Longer service life. In terms of service life, boron carbide nozzle has the longest one such as for sand

blasting and shot peening.

2. Lower cost per use. Boron carbide costs more but will outlast tungsten carbide by 3 to 10times.

3. To reduce down time.

4. To maintain efficiency.

![]()