Prepackaged Magnesium Sacrificial Anode Cathodic Protection With Backfill And Cable For Underground Pipelines Anti Corrs

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM,High Broad,None |

| Certification: | ASTM G-97 / ISO 90001 |

| Model Number: | H-1 / mic |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Kilograms |

|---|---|

| Price: | negotiable |

| Packaging Details: | On pallet with steel bundles |

| Delivery Time: | 1 FCL:14 Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 300 Metric Ton/Metric Tons per Month |

|

Detail Information |

|||

| Pack: | Cotton Bag , Plastic Bag | Surface: | Equilibrium Potential Of -2.61V |

|---|---|---|---|

| Process: | Casting / Prepackaged | Standard: | America Standard |

| High Light: | mg anode,magnesium sacrificial anode |

||

Product Description

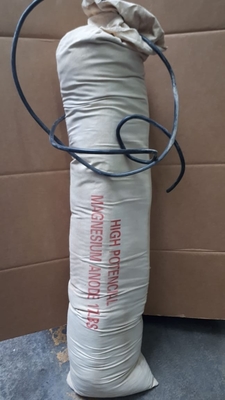

Cathodic Protection Prepacked Magnesium Anode, SacrificialMagnesium Anode

It is made of recyclable materials or easily decomposable materials and the content of harmful elements in the backfill is lower than safety standards, which will not bring any pollution to the surrounding.

The available cables type (insulation/sheath) are: PVC/PVC, XLPE/PVC, HMWPE etc. with any required size.

| Backfill Element | |

| Gypsum | 75% |

| Bentonite | 20% |

| Sodium Sulphate | 5% |

| Harmful Elements | |

| Cadmium (Cd) | ≤1ppm |

| Arsenicum (As) | ≤1ppm |

| Mercury (Hg) | ≤1ppm |

| Phosphorus (Pb) | ≤10ppm |

Magnesium anode is casted from high-purity magnesium and installed in a backfill of 75 % gypsum, 20 % Bentonite and 5 % sodium sulfate. This type of anode produces an open circuit potential of 1.65 - 1.70 volts, which is 20 - 30 % greater than conventional magnesium anodes. This high driving voltage means greater protection can be delivered from fewer anodes.

Typical Applications

High potential anodes can be used to protect most underground buried metallic structures.

They are ideally suited for structures buried in soils with resistivities in excess of 2000 ohm.cm or containing numerous corrosion hot spots .

![]()

According to the electrochemical principle, cathodic current is provided from the alloy anode material body through soil, water and other electrolytes to the protected body such as the steel structure, so that the protected steel structure is cathodicized to achieve cathodic protection. As the current continues to flow, the anode material is continuously consumed. This is the origin of the name of the sacrificial anode.

Magnesium alloy is an ideal sacrificial anode material because of its negative anode potential, large electricity generation per unit mass and long service life. As an ideal sacrificial anode material, magnesium alloy also has the following characteristics

(1) The specific gravity is small and the potential is relatively negative

(2) High driving voltage to iron, low current efficiency

(3) Especially suitable for high resistivity medium. (For resistivity greater than 100Ω·m, it is recommended to use a strip-shaped magnesium anode)

Applicable environment

Magnesium alloy sacrificial anodes are suitable for corrosion protection of oil, gas, water supply and drainage pipelines, underground cables, chemicals, communications, harbors, ships, and reservoir gates in soil and freshwater media.

Pre-packaged magnesium alloy sacrificial anode

Pre-packaged magnesium alloy sacrificial anode: abbreviated as pre-packaged magnesium anode or set magnesium anode. In order to meet the high-tempo and rate construction requirements of engineering construction, it is assembled on the basis of the previous single magnesium alloy sacrificial anode, supplemented with set accessories. Make project construction more convenient and faster.

1. Pre-packaged magnesium anode product composition: consists of 1 magnesium sacrificial anode ingot, 1 VV-10mm2 cable, 1 filling material, 1 cotton bag, and 1 plastic woven bag. The bare anode is first connected to the cable, and the connection part is sealed with epoxy resin, and then filled in a cotton bag.

2. The function of the magnesium anode filler: it can improve the environment around the anode and ensure stable and good current efficiency; reduce the anode grounding resistance and increase the anode output current; the anode corrosion products dissolve uniformly and reduce the anode polarization rate; absorb the surrounding soil moisture, Keep the surrounding area of the anode moist for a long time; improve the current efficiency and extend the life of the anode.

![]()

Chemical compositions of Magnesium Anode

| Element | Anode type | |||||

| High Potential | AZ63B(HIA) | AZ63C(HIB) | AZ63D(HIC) | AZ31 | ||

| Mg | Bal | Bal | Bal | Bal | Bal | |

| Al | <0.01 | 5.30-6.70 | 5.30-6.70 | 5.0-7.0 | 2.70-3.50 | |

| Zn | - | 2.50-3.50 | 2.50-3.50 | 2.0-4.0 | 0.70-1.70 | |

| Mn | 0.50-1.30 | 0.15-0.70 | 0.15-0.70 | 0.15-0.70 | 0.15-0.60 | |

| Si(max) | 0.05 | 0.10 | 0.30 | 0.30 | 0.05 | |

| Cu(max) | 0.02 | 0.02 | 0.05 | 0.10 | 0.01 | |

| Ni(max) | 0.001 | 0.002 | 0.003 | 0.003 | 0.003 | |

| Fe(max) | 0.03 | 0.005 | 0.005 | 0.005 | 0.005 | |

| Other Imp.(max) | Each | 0.05 | - | - | - | - |

| Total | 0.30 | 0.30 | 0.30 | 0.30 | 0.30 | |

Electrochemical Properties

| TYPE ITEM |

Open Voltage (-V,SCE) |

Close Voltage (-V,SCE) |

Actual Capacity (A.h/LB) |

Efficiency % |

| High Potential | 1.70-1.78 | 1.50-1.60 | >500 | >50 |

| AZ63 | 1.50-1.55 | 1.45-1.50 | >550 | >55 |

| AZ31 | 1.50-1.55 | 1.45-1.50 | >550 | >55 |

Specification of Magnesium Anodes

| Type | Weight Kg(ib) |

Dimension mm(inch) | |||

| A | B | C | |||

| D type | 9D2 | 4.082(9) | 69.9(2 3/4) | 549.3(21 5/8) | 76.2(3) |

| 14D2 | 6.350(14) | 69.9(2 3/4) | 850.9(33 1/2) | 76.2(3) | |

| 20D2 | 9.072(20) | 69.9(2 3/4) | 1212.9(47 3/4) | 76.2(3) | |

| 9D3 | 4.082(9) | 88.9(3 1/2) | 352.4(13 7/8) | 95.3(3 3/4) | |

| 17D3 | 7.711(17) | 88.9(3 1/2) | 641.4(25 1/4) | 95.3(3 3/4) | |

| 32D5 | 14.515(32) | 139.7(5 1/2) | 504.8(19 7/8) | 146.1(5 3/4) | |

| 48D5 | 21.772(48) | 139.7(5 1/2) | 765.2(30 1/8) | 146.1(5 3/4) | |

| 60D4 | 27.216(60) | 114.3(4 1/2) | 114.3(4 1/2) | 1460.5(57 1/2) | |

|

C type |

Type | Diameter (mm) |

Length(mm) | Weight(Kg) | |

| High potential | AZ63 | ||||

| C25 | 75 | 336 | 325 | 2.56 | |

| C36 | 114 | 202 | 193 | 3.7 | |

| C41 | 114 | 230 | 220 | 4.2 | |

| C77 | 114 | 431 | 412 | 7.8 | |

| C100 | 114 | 560 | 536 | 10.2 | |

| C145 | 146 | 494 | 472 | 14.7 | |

| C227 | 178 | 520 | 497 | 22.9 | |

| C274 | 114 | 1528 | 1462 | 28.2 | |

|

S type |

Type | Weight Kg(lb) |

Dimension mm(inch) | |||

| A | B | C | L | |||

| 3S3 | 1.4(3) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 4.7(119.4) | |

| 5S3 | 2.3(5) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 7.7(195.6) | |

| 9S2 | 4.1(9) | 2 4/5(71.1) | 2(50.8) | 2(50.8) | 28(711.2) | |

| 9S3 | 4.1(9) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 13.6(345.4) | |

| 17S2 | 7.7(17) | 2 4/5(71.1) | 2(50.8) | 2(50.8) | 52.5(1333.5) | |

| 17S3 | 7.7(17) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 25.6(650.2) | |

| 17S4 | 7.7(17) | 4(101.6) | 3 1/5(81.3) | 4(101.6) | 18(457.2) | |

| 20S2 | 9.1(20) | 2 4/5(71.1) | 2(50.8) | 2(50.8) | 62(1574.8) | |

| 32S3 | 14.5(32) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 47(1193.8) | |

| 32S5 | 14.5(32) | 5(127.0) | 4 1/5(106.7) | 5(127.0) | 21.2(538.5) | |

| 40S3 | 18.1(40) | 3 4/5(96.5) | 3(76.2) | 3(76.2) | 60(1524.0) | |

| 48S5 | 21.8(48) | 5(127.0) | 4 1/5(106.7) | 5(127.0) | 31.5(800.1) | |

| 60S4 | 27.2(60) | 4(101.6) | 3 1/5(81.3) | 4(101.6) | 62(1574.8) | |

Contact us for pricing :

Ms. Vivian Jiang

-----------------------------------------------

China Hunan High Broad New Material Co.Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705 Fax:+86-731-85716569

Mobile/Whatsapp: +86-139-7488-3816

Email: vivian@hbnewmaterial.com

Skype: vivian.jjy