AZ61 TUBE Extruded Magnesium Alloy Products for Pressure Applications

Product Details:

| Place of Origin: | Hunan China |

| Brand Name: | HB |

| Certification: | ISO / ASTM / GB |

| Model Number: | MAG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 kgs |

|---|---|

| Price: | according to quantity |

| Packaging Details: | In case |

| Delivery Time: | 14 days |

| Payment Terms: | T/T |

| Supply Ability: | 500 mt/month |

|

Detail Information |

|||

| Shape: | Extrusion | Chemical Composition: | Magnesium Alloy |

|---|---|---|---|

| Type: | AZ31B, ME20M ,AZ80 | Thickness: | 1MM 1.5MM 2MM 3MM 5MM 10MM 50MM |

| Sacificial Anode Standard: | Mg Mn Alloy M1C AZ80 | Application: | Aircraft Parts , Marine |

| Surface Finish: | Extrusion | Magnesium Alloy Plate: | Stainless Steel Sheet |

| High Light: | Extruded Magnesium Alloy Products,Extruded Magnesium Alloy AZ61 TUBE,Magnesium Extrusion AZ61 TUBE |

||

Product Description

Product Description:

Magnesium Extrusion is a high-quality magnesium alloy product that is widely used in various industries due to its excellent properties. It is available in different types, including AZ31B, ME20M, and AZ80, catering to different needs and applications.

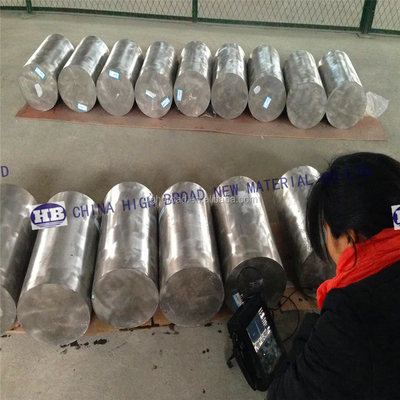

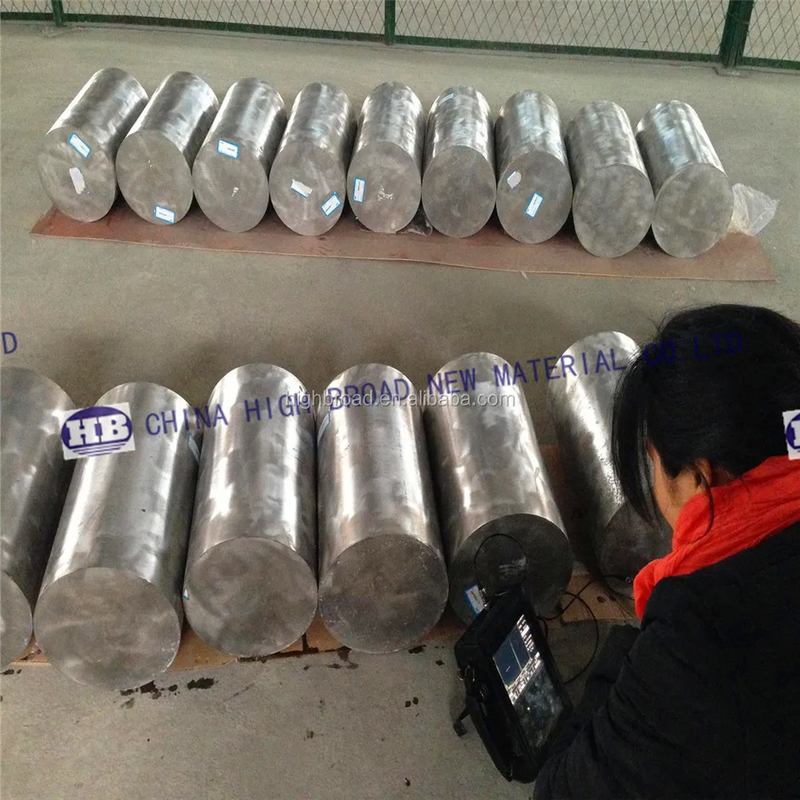

Magnesium Extrusion is a process of shaping magnesium into various forms, such as wires, rods, billets, and profiles, using pressure and heat. This process results in Magnesium Extruded Shapes, Magnesium Extruded Components, and Magnesium Extrusion Profiles, which are strong, durable, and corrosion-resistant.

- Type: AZ31B, ME20M, AZ80

- Melting Point: 650°C

- Density: 1.74g/cm³

- Machinability: Good

The different types of Magnesium Extrusion offer varying levels of strength, ductility, and corrosion resistance, making them suitable for different applications.

Magnesium has a relatively low melting point compared to other metals, making it easier to shape during the extrusion process.

Magnesium is a lightweight metal, with a density of only 1.74g/cm³, making it an ideal choice for applications where weight reduction is crucial, such as in the aerospace and automotive industries.

Magnesium Extrusion has excellent machinability, which means it can be easily cut, drilled, and shaped into various forms without losing its structural integrity.

Magnesium Extrusion is available in the following forms:

- Magnesium Wires: These are thin, flexible, and lightweight Magnesium Extruded Shapes, commonly used in electrical and electronic industries.

- Magnesium Rods: These are solid, cylindrical Magnesium Extruded Components used in various applications, such as in the production of bicycle frames and camera tripods.

- Magnesium Billets: These are large, rectangular Magnesium Extruded Shapes used as raw materials for further processing, such as forging and rolling.

- Magnesium Profiles: These are custom-shaped Magnesium Extruded Components used in various industries, such as in the construction, automotive, and marine industries.

Magnesium Extrusion offers a cost-effective and efficient way of producing high-quality magnesium alloy products with excellent mechanical and corrosion-resistant properties. Its versatility and lightweight make it a popular choice in various industries, and its availability in different forms caters to a wide range of applications. Choose Magnesium Extrusion for your next project, and experience its numerous benefits.

Features:

- Product Name: Magnesium Extrusion

- Product: Magnesium Wires / Rods / Billets / Profiles

- Content: Magnesium Alloy AZ61 TUBE

- Shape: Extrusion

- Application: Aircraft Parts, Marine

- Produce: Cast / Extrude

- Key Features:

- Extruded Magnesium Bars

- Magnesium Extruded Components

- Magnesium Extruded Profiles

- Magnesium Products

- Magnesium Alloy AZ61

Technical Parameters:

| Product Name | Technical Parameters |

|---|---|

| Sacificial Anode Standard | Mg Mn Alloy M1C AZ80 |

| Application | Aircraft Parts, Marine |

| Standard | ASTM Magnesium Alloy Extrusions |

| Content | Magnesium Alloy AZ61 TUBE |

| Product | Magnesium Wires / Rods / Billets / Profiles |

| Type | AZ31B, ME20M, AZ80 |

| Shape | Extrusion |

| Chemical Composition | Magnesium Alloy |

| Magnesium Alloy Plate | Stainless Steel Sheet |

| Surface Finish | Extrusion |

| Extruded Magnesium Products | Magnesium extruded bars, components and profiles |

| Extruded Magnesium Bars | Various lengths and diameters available |

| Magnesium Extruded Components | Custom sizes and shapes can be produced according to customer's specifications |

Applications:

Magnesium Extrusion is a type of magnesium alloy product that is produced through the process of extrusion. It is manufactured by HB, a reputable company based in Hunan, China, and has obtained various certifications such as ISO, ASTM, and GB. The model number for this product is MAG and the minimum order quantity is 100 kgs. The price is determined by the quantity ordered and the packaging details are provided in case to ensure safe delivery. The estimated delivery time for this product is 14 days and the payment terms are T/T. With a supply ability of 500 mt/month, HB is able to cater to the needs of its customers efficiently.

Magnesium Extrusion is widely used in various industries due to its lightweight, high strength, and corrosion resistance properties. It is commonly used in the automotive, aerospace, and electronic industries. The extruded magnesium profiles and shapes are used to create structures, frames, and components for vehicles, aircraft, and electronic devices. The magnesium extrusion profiles are also used in the construction industry for lightweight and durable building materials.

The surface finish for magnesium extrusion is extrusion, which provides a smooth and polished look. This makes it suitable for applications where aesthetics are important. The types of magnesium alloys available for extrusion include AZ31B, ME20M, and AZ80. These alloys have different properties and are used for different purposes depending on the specific needs of the customer.

The melting point for magnesium extrusion is 650°C, making it suitable for high-temperature applications. Additionally, magnesium alloy plates can also be produced through the process of extrusion. These plates are comparable to stainless steel sheets in terms of strength and durability, but are much lighter in weight. This makes them a popular choice for various industries, especially in applications where weight reduction is crucial.

The content of magnesium alloy AZ61 tube is another important aspect of this product. The AZ61 alloy is a combination of magnesium and aluminum, with a small amount of zinc. This results in a strong and lightweight product that is ideal for applications where high strength and low weight are crucial. The tube shape makes it versatile for various uses, and it is commonly used in the automotive, aerospace, and electronic industries.

In conclusion, HB MAG, with its extruded magnesium profiles and shapes, offers a high-quality and versatile product that is suitable for various applications. Its lightweight, high strength, and corrosion resistance properties make it a popular choice in industries such as automotive, aerospace, and construction. With its efficient supply ability and various certifications, HB is a reliable source for magnesium extrusion products.

Customization:

Brand Name: HB

Model Number: MAG

Place of Origin: Hunan China

Certification: ISO / ASTM / GB

Minimum Order Quantity: 100 kgs

Price: according to quantity

Packaging Details: In case

Delivery Time: 14 days

Payment Terms: T/T

Supply Ability: 500 mt/month

Thickness: 1MM 1.5MM 2MM 3MM 5MM 10MM 50MM

Type: AZ31B, ME20M, AZ80

Sacificial Anode Standard: Mg Mn Alloy M1C AZ80

Standard: ASTM Magnesium Alloy Extrusions

Application: Aircraft Parts, Marine

Extruded Magnesium Profiles and Shapes, Magnesium Extruded Shapes, Extruded Magnesium Alloy Products

FAQ:

-

Q: What is the brand name of this product?

A: The brand name is HB. -

Q: What is the model number of this product?

A: The model number is MAG. -

Q: Where is this product manufactured?

A: It is made in Hunan, China. -

Q: What certifications does this product have?

A: This product is certified with ISO, ASTM, and GB standards. -

Q: What is the minimum order quantity for this product?

A: The minimum order quantity is 100 kgs. -

Q: How is the price determined for this product?

A: The price is determined according to the quantity ordered. -

Q: What kind of packaging is used for this product?

A: This product is packaged in cases. -

Q: How long does it take for this product to be delivered?

A: The delivery time is 14 days. -

Q: What are the accepted payment terms for this product?

A: We accept T/T payments. -

Q: What is the supply ability for this product?

A: The supply ability is 500 mt/month.