OEM WE43 Magnesium Alloy Plate for aero-engines / sports

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad/OEM |

| Certification: | ISO |

| Model Number: | AZ31B,AZ61,AZ91D,ZK60,WE43 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1000 kgs |

|---|---|

| Price: | negotiable |

| Packaging Details: | first in carton, then on pallet |

| Delivery Time: | 100 kgs: 7 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal,West Union |

| Supply Ability: | 100mt/month |

|

Detail Information |

|||

| Name: | Magnesium Photoengraving Plate WE43 | Material: | Magnesium Alloy Plate WE43 |

|---|---|---|---|

| Key Words: | Magnesium Alloy WE43 | Key Word: | Magnesium Plate WE43 |

| Detail Function: | Magnesium Alloy Plate For CNC Engraving,Embossing,Etching,Stamping | Type: | Engraving Magnesium Alloy Plate WE43 |

| Other Name: | Etching Magnesium Sheet WE43 | Application 2: | WE43 Magnesium Alloy Sheet For Helicopter Transmissions, Power Systems, Aero-engines, Sports |

| High Light: | magnesium engraving plate,magnesium billet |

||

Product Description

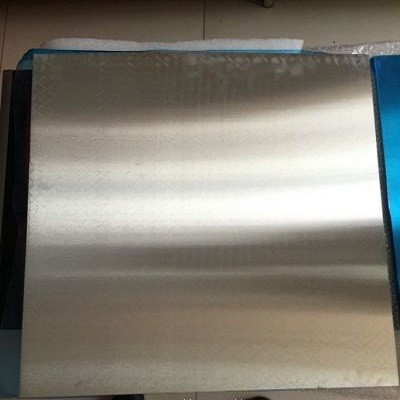

OEM WE43 Magnesium Alloy Plate for aero-engines / sports

Magnesium plate WE43

WE43 is a wrought magnesium base alloy with good room-temperature strength and ductility combined with corrosion resistance and weldability. Increased strength is obtained by strain hardening with a subsequent partial anneal (H24 and H26 tempers).

Specifications:

Commodity : Coated Magnesium Alloy Plate for Etching

Content: Magnesium Alloy

Process : Extruded

Application: Etching Plate

Type : WE43

Size Range:

Sheet: thickness from 0.5mm to 7mm; Max. width is 600mm; Max. length is 1200mm;

Chemical Composition:

Al: 2.5-3.5%; Zn: 0.7-1.3%; Mn: 0.20 – 1.0%; Mg: Balance

PHYSICAL PROPERTIES:

Density: 1.78

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa

Poissons ratio: 0.35

Melting range: 566 - 632°C

|

Specification |

Chemical (%) |

||||

|

Y |

Gd |

Nd |

Zn |

Zr |

|

|

WE54 |

4.71-5.5 |

1.0-2.0 |

1.5-2.0 |

- |

0.4-1.0 |

|

WE43 |

3.7-4.3 |

0-1.9 |

2.0-2.5 |

- |

0.4-1.0 |

|

WE94 |

3.5-4.5 |

8.5-9.5 |

- |

1-1.5 |

0.4-0.7 |

|

Specification |

Thermal Treatment Status |

Tensile Properties |

||

|

0.25% Proof Stress |

Tensile Strength |

Elongation % |

||

|

(Mpa) |

(Mpa) |

|||

|

WE43 |

T5 |

234 |

306 |

8 |

|

Specification |

Thermal Treatment Status |

Tensile Properties |

||

|

0.25% Proof Stress |

Tensile Strength |

Elongation % |

||

|

(Mpa) |

(Mpa) |

|||

|

WE54 |

T5 |

205 |

280 |

4 |

|

Specification |

Thermal Treatment Status |

Tensile Properties |

||

|

0.25% Proof Stress |

Tensile Strength |

Elongation % |

||

|

(Mpa) |

(Mpa) |

|||

|

WE94 |

T5 |

370 |

450 |

6 |

Application:

WE series magnesium alloys are magnesium based with Gadolinium, Yttrium, Zinc and Zirconium. It covers WE43,WE54 and WE94.All those are high strength casting alloys which can be used in temperatures of up to 300oc (572of). The alloys have good mechanical properties coupled with excellent corrosion resistance. The alloys are widely applied in : Helicopter transmissions, power systems, aero-engines, sports cars, missiles.

Magnesium Alloy Plate Processing

![]()