OEM Bulletproof Ceramic Plates / SIC Bulletproof Ceramic Plates

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM/High Broad |

| Certification: | ISO |

| Model Number: | NIJ III IV silicon carbide & UHMWPE insert bulletproof vest plate |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 kilograms |

|---|---|

| Price: | negotiable |

| Packaging Details: | Each nozzle packed in a plastic tube, then in a carton |

| Delivery Time: | 10 tons:14Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 100 MT per month |

|

Detail Information |

|||

| Name: | NIJ IV Defended Ballistic Bulletproof Plate | Keyword: | Ballistic Plates For Army SAPI, NIJ Level III Alumina+PE Bulletproof Plate, Armor Plate |

|---|---|---|---|

| Advantage: | Bulletproof Plate For Ballistic Vest Body Armor Plate NIJ Standard | Grade: | NIJ III, NIJ IV |

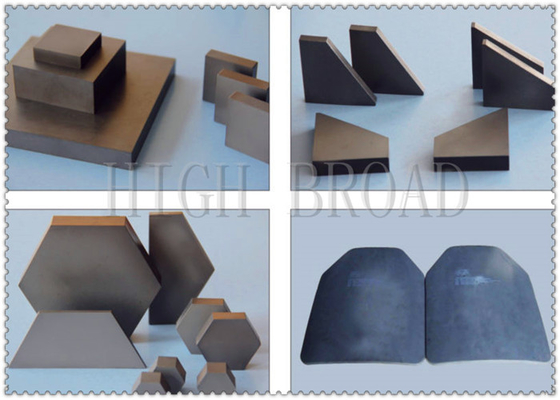

| Shape: | Squre,hexongal,rectangular, Round | Content: | SIC SILICON BARDE BULLETPROOF PLATE |

| Density: | 3.1g/cm3 | NIJ III, NIJ IV: | NIJ Class Level IV Bulletproof Ceramic Body Armor Plate |

| High Light: | silicon carbide tiles,bulletproof ceramic plates |

||

Product Description

SILICON CARBIDE Bulletproof Plate

Widely used in heavy armored protection in planes/vehicles/ships, and high-class physical protection.

Specifications:

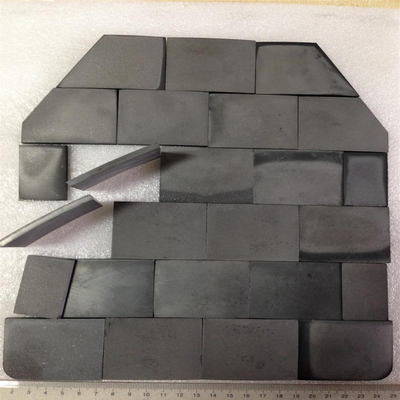

Sintered Silicon Carbide(S-SIC)Bulletproof Tiles

1 Ideal Armor Material

2. Lightweight

3. Hardness

4.All shape customized

Key Features:

♦ Ideal Armor Material in lightweight and performance cost efficient compare with Boron Carbide and Alumina

♦ Lower weight with higher performance efficient.

♦ It is manufactured by pressureless sintering.or Reaction-Bonding

Applications:

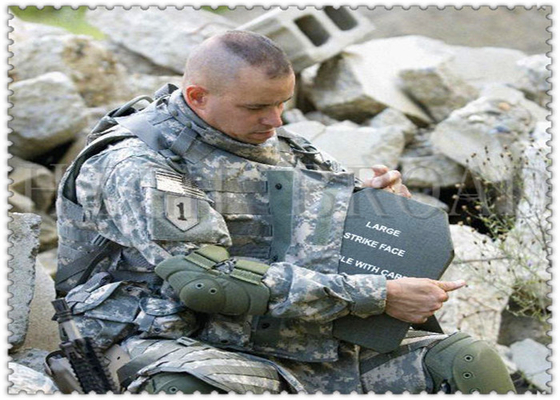

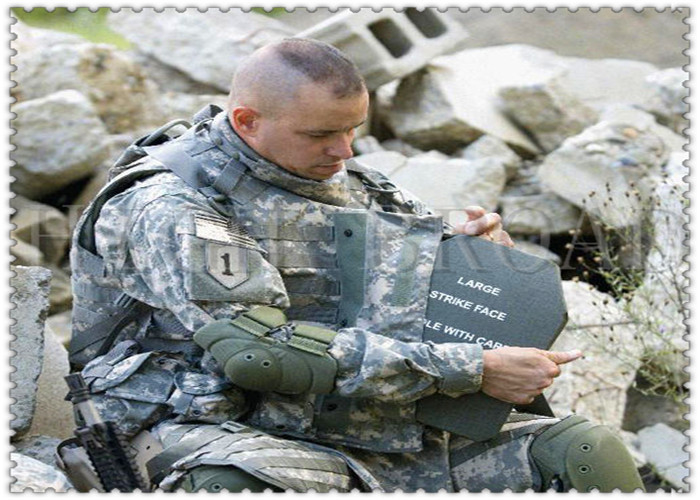

♦ Body Armor Plates

♦ High-Tech Vehicle Armor Protection and Watercraft defence.

Dimensions:

♦ Various shapes and qualities customized for applications and threat level

Research and development:

♦ HIGH BROAD has an excellent team of great scientists and experienced technicians, keeping the company at the forefront of ceramic technology. we have a Survivability Centre where our scientists research the latest protective materials. And we cooperated with many universities, research institutions and other R&D facilities, the company is working on the development of new materials to meet for future vehicle and body armor requirements.

Quality assurance:

All of HIGH BROAD armor ceramics used in finished armor products are tested and proven ballistic performance for National Institute of Justice (N.I.J) and European design standards.

Specifications:

|

Density: 2.40-2.65 g/cm3 Elastic modulus: 510 Gpa Knoop Hardness: 3300 Flexural strength: 400-650 Mpa Compressive strength: 4100 Mpa Fracture toughness: 4.5-7.0 Mpa.m1/2 Coefficient of thermal expansion: 4.5x106 Thermal Conductivity: 29 m0k Maximum permissible service temperature in air: 1500℃ |

Material Comparation Chart:

|

Item |

Al2O3 |

SiC |

B4C |

|

Density |

3.5g/cm3 |

3.1g/cm3 |

2.4-2.65g/cm3 |

|

Hardness |

HV1650 |

HV2750 |

HV3300 |

|

Flexural strength |

290 Mpa |

380 Mpa |

400-650 Mpa |

|

Compressive strength |

850 Mpa |

3970 Mpa |

4100 Mpa |

|

Fracture toughness |

4.8 Mpa.m1/2 |

4.0 Mpa.m1/2 |

4.5-7.0 Mpa.m1/2 |

|

Thermal Conductivity |

20 m0k |

120m0k |

29 m0k |

|

Coefficient of thermal expansion |

7.2x106 |

4x106 |

4.5x106 |

Company Brief Introduction:

Basic Information Hunan High Broad New Material Co., Ltd.

| Business Type: | Manufacturer, Trading Company | |

| Main Products: | Boron Carbide,Silicon Carbide,Boron Carbide parts,Silicon Carbide parts,Ceramic products | |

| Number Of Employees: | 80 - 100 People |

Trade & Market

| Main Markets: |

Eastern Asia (and your area) |

|

| Total Annual Sales Volume: | US$5 Million - US$10 Million | |

| Export Percentage: | 85% - 95% |

Factory Information

| Factory Size (Sq.meters): | 15,000-28,000 square meters | |

| Factory Location: | changsha,hunan P.R. China | |

| No. of Production Lines: | 60 | |

| Number of R&D Staff: | 10 - 20 People | |

| Number of QC Staff: | 10 - 20 People | |

| Certifications: | ISO9001,ISO14001,EJ/T9001-2005 | |

| Contract Manufacturing: | OEM Service Offered Buyer Label Offered |

Supplier Assessment Report

| Supplier Assessment Reports are detailed on-line reports about the supplier's capabilities. It helps you get all the information you need to trade confidently with suppliers. |

Company Principle:

Our Belief: Continuous Innovation.

Our Spirit: Sincerity, Unity, Dedicated, Hardworking.

Our Mission: Provide most advanced products & most professional technical solution.