Boron carbide nozzle for sandblast , straight bore nozzles mould available

Product Details:

| Place of Origin: | China |

| Brand Name: | OEM/High Broad |

| Certification: | ISO, DNV,BV |

| Model Number: | Hotpress B4C Nozzle ceramic sandblast nozzle |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 pieces |

|---|---|

| Price: | negotiable |

| Packaging Details: | Each nozzle packed in a plastic tube, then in a carton |

| Delivery Time: | 500 pieces:15 Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 1000 pieces per month |

|

Detail Information |

|||

| Name: | Hotpress Sandblasting Boron Carbide Spray Nozzle For Cleaning Equipment | Keyword: | Sandblast Venturi Nozzle Double Inlet Venturi Nozzle For Chemical Industry |

|---|---|---|---|

| Advantage: | High Temperature Resistance, Abrasion-resistance, Light Unit Weight, Working Life Much Longer Than Tradition Material | Material: | B4C SIC Ceramic Sandblast Nozzle |

| Shape: | Straight Core,Ventui Type Venturi Sandblasting Boron Carbide Nozzles | Usage: | Sandblasting Machines, Hydraulic Cutters, Power Plant Boilers |

| Thread: | Coarse Thread, Thin Thead, Fine Thread | Rubber Jacket: | Coarse Thread Long Venturi Boron Carbide Rubber Jacket Sand Blast Nozzles |

| Boron Carbide Abrasives Nozzles: | Manufacturing Blast Nozzle Boron Carbide Nozzle | ||

| High Light: | sandblaster nozzle,sand blast nozzle |

||

Product Description

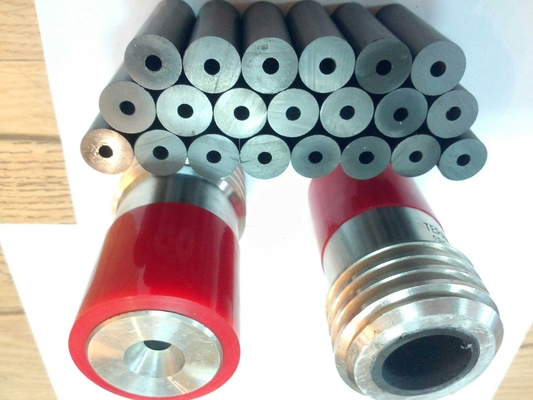

Boron carbide nozzle for sandblast , straight bore nozzles mould available

Boron carbide nozzle straight bore nozzles all boron carbide nozzle mould available boron carbide nozzle for sandblasting

High temperature resistance, Abrasion-resistance, light unit weight, working life much longer than tradition material.

|

Regular size list for straight core

Other sizes:

Venturi type:

Coarse thread and Fine thread

Boron carbide nozzle insert with Aluminum or stainless steel jacket

(mm)

|

Density: 2.40-2.65 g/cm3

Elastic modulus: 510 Gpa

Knoop Hardness: 3300

Flexural strength: 400-650 Mpa

Compressive strength: 4100 Mpa

Fracture toughness: 4.5-7.0 Mpa.m1/2

Coefficient of thermal expansion: 4.5x106

Thermal Conductivity: 29 m0k

Maximum permissible service temperature in air: 1500℃

Material Comparation Chart:

|

Item |

Al2O3 |

SiC |

B4C |

|

Density |

3.5g/cm3 |

3.1g/cm3 |

2.4-2.65g/cm3 |

|

Hardness |

HV1650 |

HV2750 |

HV3300 |

|

Flexural strength |

290 Mpa |

380 Mpa |

400-650 Mpa |

|

Compressive strength |

850 Mpa |

3970 Mpa |

4100 Mpa |

|

Fracture toughness |

4.8 Mpa.m1/2 |

4.0 Mpa.m1/2 |

4.5-7.0 Mpa.m1/2 |

|

Thermal Conductivity |

20 m0k |

120m0k |

29 m0k |

Company Principle:

Our Belief: Continuous Innovation.

Our Spirit: Sincerity, Unity, Dedicated, Hardworking.

Our Mission: Provide most advanced products & most professional technical solution.

Office, Workshop, Inspection Lab:

product show:

![]()