Buried Structure Immersed Structure Magnesium Anodes Corrosion Prevention

Product Details:

| Place of Origin: | China |

| Brand Name: | HB Magnesium anode for cathodic protection anti corrosion |

| Certification: | ISO9001/14001 |

| Model Number: | ASTM G97 America magnesium anode |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 kg |

|---|---|

| Price: | negotiable |

| Packaging Details: | On pallet with steel bundles |

| Delivery Time: | 14 days: 20mt |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,Credit Card,PayPal |

|

Detail Information |

|||

| Magnesium Anode Type: | Condenser Anode Horse Shoe Anode | Magnesium Anode: | Magnesium Anode (anode With Cable) |

|---|---|---|---|

| Prepackage Mg Anode: | Backfill | Grade: | High Potential |

| Az63 Magnesium Anode: | Magnesium Anode With Filling Stuff | Similar Products: | ASTM Zinc Anodes With Double Iron Feet For Ships ASTM B418-95 US Mill 18001 K |

| High Light: | sacrificial anode protection,magnesium sacrificial anode |

||

Product Description

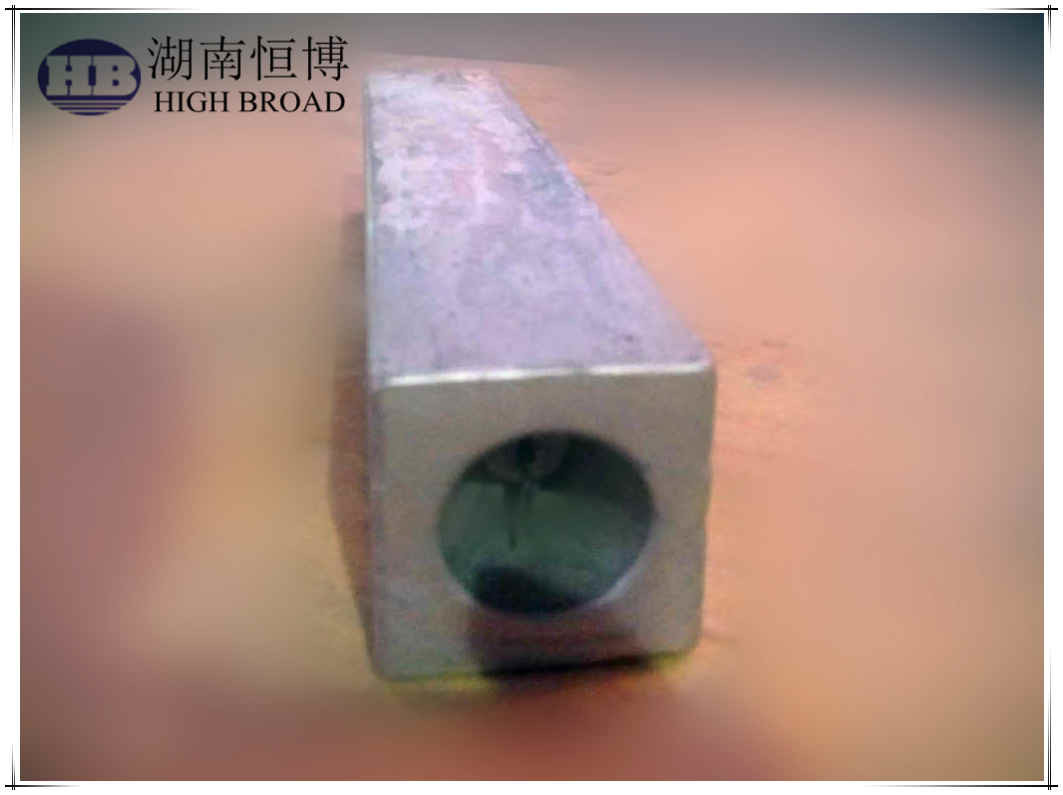

Our High Potential Magnesium anodes are produced of high purity Mg metal ingot with high quality tested according to ASTMG-97 standart Due to the adopted special manufacturing technology, our anodes have superior electro-chemical properties and in course of protecting, the nodes consumed uniformly from the surface. Therefore, the anodes have a longer life. In practical experience the actual measured driving potential is between -1,80 V to -1,85 V, thus provide most powerful protectionto the targetted structure. We suggest to use our high potential Mg anodes in soils with resistivities higher than 2000 Ωcm

Magnesium anodes are widely used in cathodic protection, as Mg metal has the more negative potential than other galvanic materials. We take the most professional and reasonable technical control through melting of Mg metal, choosing of Mg ingot and control the impurities, preparing of Mg alloy smelting, refining of Mg alloy, pouring and casting of anode, making mould, connecting of cable and final test.

![]()

![]()

Application:

They are used in protecting against corrosion of such insfrastructures :

· Chemical storage tanks of fuel oil, from crude oil tanks in the inner and outer surfaces,

· Oil, gas, water supply pipelines,

· Underground oil

· Fuel and water tanks,

· Boilers and hot water boilers in the water heater,

· The inner surface of the sea water transport pipes,

· Fresh / salt water in the metal structure, and quays, port legs, ships, platforms,

· Offshore pipelines

· Any other structure corrroded.

![]()

![]()

FAQ

Contact me for more details:

Skype: Vivian.jjy