Hand Tool Parts Sandblasting Nozzle Boron Carbide Nozzle For Cleaning Equipment

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad Boron Carbide Nozzle for sandblast |

| Certification: | CE, ISO ceramic nozzles |

| Model Number: | Boron Carbide Nozzles |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 pieces |

|---|---|

| Price: | negotiable |

| Packaging Details: | In export carton box |

| Delivery Time: | 3-20 working days |

| Payment Terms: | D/A, L/C, D/A, D/P, T/T, Western Union, MoneyGram,Credit Card,PayPal |

| Supply Ability: | 50000 pieces/year |

|

Detail Information |

|||

| Type: | Hand Tool Parts | Hand Tool Parts: | Boron Carbide Nozzles For Sandblast |

|---|---|---|---|

| Applications: | For Sandblasting,Gas Cleaning,Dust Control,Desulph | B4C: | Oil Drill Sandblasting Nozzles (Boron Carbide Nozzle) |

| Boron Carbide: | Sandblasting Nozzles Factory | Boron Carbide Venturi Nozzle: | Boron Carbide Venturi Nozzle |

| Boron Carbide Straight Nozzle: | Boron Carbide Straight Nozzle | B4C Density: | 2.48g/cm^3 |

| High Light: | sandblaster nozzle,sand blast nozzle |

||

Product Description

Boron carbide nozzles offer the longest wear life of any standard nozzle material.

Peak nozzle production performance is maintained for longer periods with optimum consumption of air

and abrasive. Boron carbide nozzles typically outwear tungsten carbide nozzles by five to ten times

and silicon carbide by two to three times. Boron carbide nozzles are recommended for use with abrasives

such as aluminum oxide and aggressive mineral aggregates.

Our selection of nozzles is unmatched, anywhere

We have standard products that can replace the original nozzles installed on most equipment.

We also have higher performance upgrades for most OEM products to allow you to achieve optimum

blasting effectiveness, efficiency and reduce your total costs.

Approximate Nozzle Service Life in Hours *

Nozzle material Steel Shot and Grit Expendable Abrasives Alu-oxide Abrasives

Ceramic 20 - 40 10 - 30 1-4

Tungsten Carbide 500 - 800 300 - 400 20-40

Silicon Carbide / Nitride 600 - 1000 400 - 600 50-100

Boron Carbide 1500 - 2500 750 - 1500 200 – 1000

![]()

![]()

![]()

* Estimated values for comparison. Actual service life will vary depending upon

blast pressure, media size and particle shape.

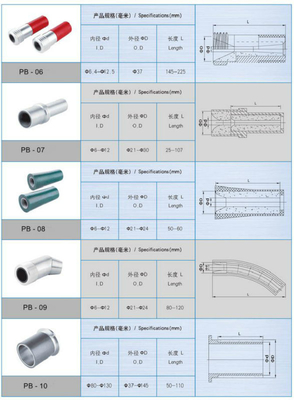

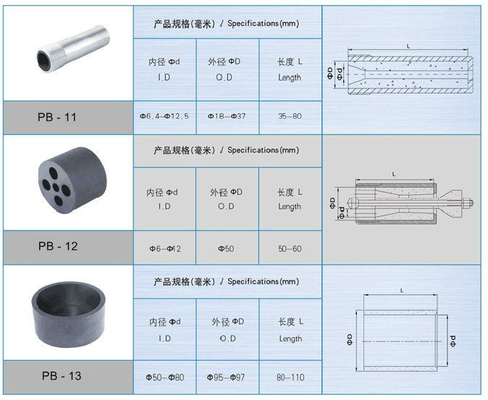

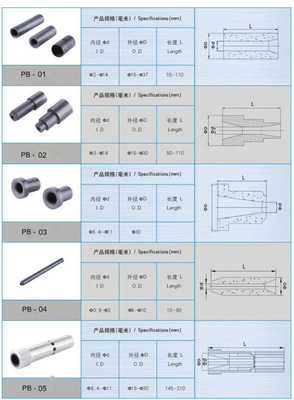

different models as following :

| Model | Bore Dia | Length | Inlet |

| HST-ABN-5 | 5mm(3/16) | 100mm(4) | 25mm(1) |

| HST-ABN-6 | 6mm(15/64) | 125mm(4 7/8) | 25mm(1) |

| HST-ABN-7 | 7mm(9/32) | 130mm(5 1/8) | 32mm(1 1/4) |

| HST-ABN-8 | 8mm(5/16) | 145mm(5 1/16) | 32mm(1 1/4) |

| HST-ABN9 | 9mm(23/64) | 175mm(6 7/8) | 32mm(1 1/4) |

| HST-ABN-10 | 10mm(25/64) | 175mm(6 7/8) | 32mm(1 1/4) |

| HST-ABN-11 | 11mm(7/16) | 180mm(7) | 32mm(1 1/4) |

| HST-ABN-12 | 12mm(15/32) | 180mm(7) |

32mm(1 1/4) |

![]()

The working life of BC boron carbide sandblasting nozzle is 10-15times than Tungsten steel nozzle

Specification:

Grind resistant, do not active with acid, low & high temperature resistance,

The density> =2.46g/cm3;

Hardness> =3500kgf/sqm, bending resistance: ≥ 400Mpa

Melting point: 2450degree

And now boron carbide nozzle is instead of hardness alloy, Tungsten carbide nozzle, silicon carbide sandblasting nozzle.

The working life of boron carbide nozzle is 500-1000H

The size can be customized as per drawing

| Material | Length(mm) | OD(mm) | ID(mm) |

| Boron carbide | 35 | 20 | 8,10 |

| Boron carbide | 60 | 20 | 6,8,10 |

| Boron carbide | 55 | 20 | 8,10 |

| Boron carbide | 55 | 20 | 6 |

| Boron carbide | 45 | 20 | 6 |

| Boron carbide | 80 | 20 | 6,8,10 |

| Boron carbide | 45 | 20 | 8,10 |

| Boron carbide | 45 | 15 | 8,10 |

| Boron carbide | 82 | 21 | 6,8,10 |

| Boron carbide | 55 | 15 | 6,8 |

![]()