99.95% Pure Magnesium Alloy Sheet / Plate For CNC Engraving / Embossing

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad/OEM |

| Certification: | ISO |

| Model Number: | Pure Magnesium Plate / magnesium Sheet |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg for 99.95% Pure Magnesium Plate |

|---|---|

| Price: | negotiable |

| Packaging Details: | In carton, on pallet for Magnesium plate/sheet |

| Delivery Time: | 1days for 10tons |

| Payment Terms: | D/P, L/C, T/T, Western Union, MoneyGram,Paypal etc |

| Supply Ability: | 300mt per month |

|

Detail Information |

|||

| Product Name: | High Quality And Low Price 99.9% Pure Magnesium Plate | Application: | CNC Engraving,Embossing,Etching,Stamping |

|---|---|---|---|

| Plate Type: | Hot Roll, Extruded,Cast | Material: | Magnesium Alloy |

| Industrial Plate: | Computer, Printing, Camera, Cellphone | Other Name: | Magnesium Plate/sheet |

| High Light: | magnesium engraving plate,magnesium photoengraving plate |

||

Product Description

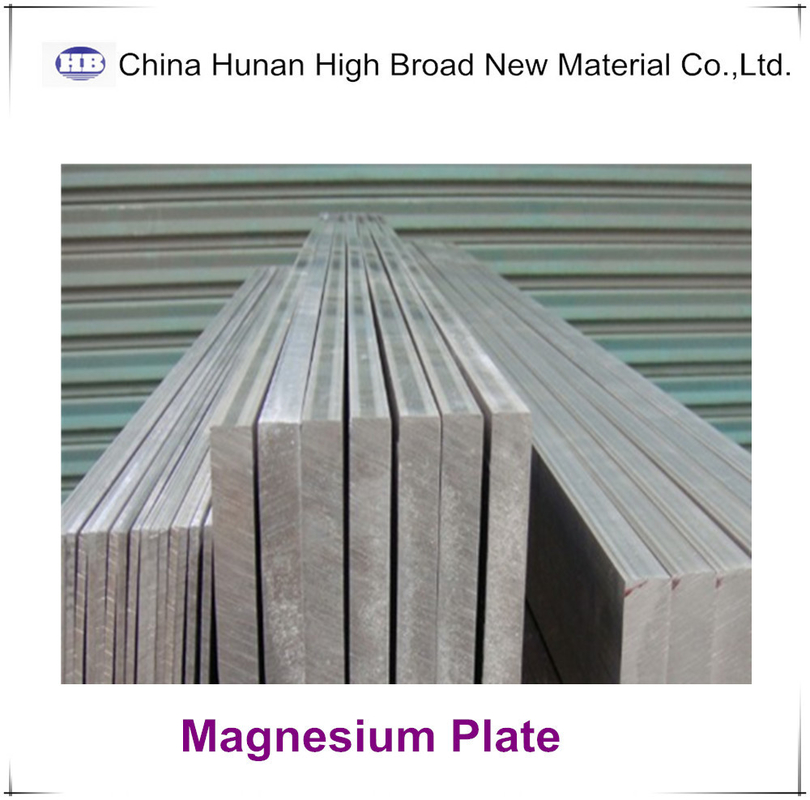

99.95% Pure Magnesium Plate / magnesium Sheet

1. Product information

• Item name: Magnesium plate/sheet

Sheet: Tks: 1 - 6mm; Max. width: 600mm;

Plate: Tks: 6 - 200mm; Max. width: 2500mm;

Max. length: 6000mm

Pure magnesium Sheet, Plate, Block and coil

It is a wrought magnesium base alloy with good room-temperature strength and ductility combined with corrosion resistance and weldability. Increased strength is obtained by strain hardening with a subsequent partial anneal (H24 and H26 tempers).

![]()

![]()

2.Size Range:

Sheet: thickness from 1mm to 6mm; Max. width is 600mm; Max. length is 6000mm;

Plate: thickness from 6 mm to 200mm; Max. width is 2500mm; Max. length is 6000mm;

Block: We can supply cut-to-size blocks according to customer's requirements.

Coil: thickness from 0.5 to 2.7mm, max. width 240mm;

Magnesium sheet/plant detail image

![]()

![]()

![]()

![]()

We can surely produce magnesium plate/sheet as per your drawing !

Pls contact us for more details !

China Hunan High Broad New Material Co., Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705

Mobile/Whatsapp: +86-139-7515-2932

Specification

ASTM B90/B90M-07; AMS 4375; AMS 4376; AMS 4377

CHEMICAL COMPOSITION

Al: 2.5-3.5%; Zn: 0.7-1.3%; Mn: 0.20 – 1.0%; Mg: Balance

PHYSICAL PROPERTIES

Density: 1.78;

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa;

Poissons ratio: 0.35;

Melting range: 566 - 632°C

HEAT TREATMENT

No thermal treatment is available for increasing the strength of this alloy after fabrication.

MECHANICAL PROPERTIES

| Alloy and Temper | Thickness (mm) |

Yield Strength 0.2% offset (MPa) |

Tensile strength (MPa) |

Elongation In 5.65 √A (%) |

| AZ31B-O | 0.5 – 1.5 | 125 | 221 | 10 |

| 1.5 – 6.3 | 105 | 221 | 9 | |

| 6.3 - 75 | 105 | 221 | 8 | |

| AZ31B-H24 | 0.5 – 6.3 | 200 | 269 | 5 |

| 6.3 -9.5 | 179 | 262 | 7 | |

| 9.5 – 12.7 | 165 | 255 | 8 | |

| 12.7 - 25 | 152 | 248 | 8 | |

| 25- 50 | 138 | 234 | 6 | |

| 50 - 80 | 124 | 234 | 7 | |

| AZ31B-H26 | 6.3 - 10 | 186 | 269 | 6 |

| 10 – 12.5 | 179 | 262 | 6 | |

| 12.5 - 20 | 172 | 255 | 5 | |

| 20 – 25 | 159 | 255 | 5 | |

| 25 - 40 | 152 | 241 | 5 | |

| 40 - 50 | 148 | 241 | 5 |

The sheet and plate shall conform to the tensile requirements in above Table unless other agreement is made between seller and purchaser. Mechanical Properties for sizes and tempers not shown in above Table shall be as agreed upon by seller and purchaser.

6.OTHER PROPERTIES

Typical Hadness

O temper: 67 Rockwell E;

H24 temper: 83 Rockwell E

WELDABILITY

Excellent weldability with gas shielded arc using AZ61A (preferred) or AZ92A filler rod; post weld stress relief is required to prevent stress corrosion cracking. Resistance welding is excellent.

MACHINING

AZ31B, like all magnesium alloy sheet and plate, machines faster than any other metal. Providing the geometry of the part allows, the limiting factor is the power and speed of the machine rather than the quality of the tool material. The power required per cubic centimeter of metal removed varies from 9 to 14 watts per minute depending on machining operation.

DENT RESISTANCE

Weight for weight, AZ31B-H24 has proven to be superior to competitive materials in its resistance to denting at moderate energy levels.Dent Resistance of 1mm Gauge Sheet (Dent depth in mm from 25mm spherical redius indentor on 350mm span)

| Impact Energy 0.34 J | Impact Energy 0.62 J | Impact Energy 1.25 J | |

|

AZ21B-H24 6061 – T6 3003 – H14 5052 – H34 2024 – T6 SAE 1010 Mild Steel |

0.66 0.94 2.24 1.55 0.99 1.09 |

1.42 1.52 3.23 2.41 1.52 1.70 |

2.34 2.46 4.90 3.35 2.29 2.67 |

SURFACE TREATMENT

All the normal chromating, anodizing, plating, and finishing treatment are readily applicable. AZ31B also responds well to plasma electrolytic oxidation finishing

7.Contact us for more information:

Jane Hu(Ms)

China Hunan High Broad New Material Co., Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705

Mobile/Whatsapp: +86-139-7515-2932