Hot Rolling / Extruding We43-T5 Magnesium Alloy Plate 0.3mm 0.5 Mm 0.7mm

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad or OEM |

| Certification: | ISO |

| Model Number: | AZ31B,AZ91D,ZK60,WE43 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 100 kgs |

|---|---|

| Price: | negotiable |

| Packaging Details: | In export plywooden case |

| Delivery Time: | 1000 kgs: 5 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 1000mt/month |

|

Detail Information |

|||

| Material: | Magnesium Alloy Plate | Application: | CNC Engraving,Embossing,Etching,Stamping |

|---|---|---|---|

| Type: | Hot Rolling , Extruded, Cast Roll | Surface: | Silver Smooth |

| Industrial: | Computer,Printing,Camera,Cellphone | Commom Type: | Magnesium Alloy Sheet Az31 Az31b Az61 Plate Material |

| Process: | Wedging, Perforating, Welding, Saw Cutting, Roll Forming | Related: | Magnesium Alloy Plate |

| Similar: | Magnesium Alloy Slab | Other: | Magnesium Alloy Billet |

| High Light: | metal sheet plate,magnesium etching plate |

||

Product Description

we43-T5 magnesium TOOLING plate From 1″ to 50″ thickness for wedging, perforating, welding, saw cutting, roll forming

Used for:

shearing, stamping, punching, drilling, bending, flame cutting, expanding, swedging, perforating, welding, saw cutting, roll forming, grinding, coating, assembly, packaging, labeling, blanchard grinding, sonic testing & trepanning

Specifications:

Material : Magnesium alloy plate / Magnesium alloy Sheet

Type : WE43

Sheet Size Range:

Thickness : 0.3mm , 0.5 mm, 0.7mm, 1.0mm, 1.5mm , 1.75mm , 2mm

Width x Length: can be anysize.

PHYSICAL PROPERTIES:

Density: 1.78

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa

Poissons ratio: 0.35

Melting range: 566 - 632°C

Applications:

Where is Magnesium used?

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

Why Magnesium?

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

- We supply AZ31, AZ61, AZ80, and ZK60 Alloys, among others

Magnesium is the third-most-commonly-used structural metal, following iron and aluminum.

The main applications of magnesium are, in order: component of aluminum alloys, in die-casting (alloyed with zinc), to remove sulfur in the production of iron and steel, the production of titanium in the Kroll process.

Magnesium, in its purest form, can be compared with aluminum, and is strong and light, so it is used in several high-volume part manufacturing applications, including automotive and truck components.

Magnesium sheet and plate find application in medium strength service at temperatures below 150C. Diverse uses including aircraft fuselage, concrete tools, cell phone, camera, notebook computer cases and textile machinery.

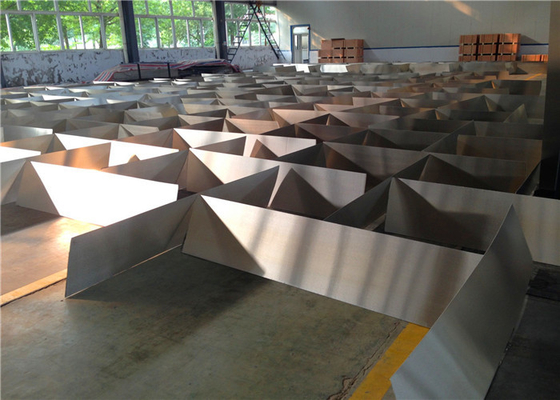

workshop:

![]()

Other Products you may have interests:

AZ91D Magnesium plate

WE54 Magnesium plate

WE94 Magnesium plate

ZK60 Magnesium plate

HP Magnesium plate

99.9% Pure Magnesium plate

We supply Magnesium alloy sheet with competitive price and quality.

| Alloy | Thickness(mm) |

Tensile strength Rm (N/mm²) |

Yield strength Rp0.2 (N/mm²) |

Elongation (A%) 50mm |

| AZ31B | 0.3-3.00 | 260 | 170 | 24.0 |

| 3.00-10.00 | 230 | 140 | 18.0 | |

|

M2M |

0.80-3.00 | 190 | 110 | 6.0 |

| 3.00-5.00 | 180 | 100 | 5.0 | |

| 5.0-10.00 | 170 | 90 | 5.0 | |

| AZ40M | 0.50-3.00 | 280 | 180 | 17.0 |

| 3.00-5.00 | 260 | 160 | 14.0 | |

| AZ41M | 0.80-3.00 | 290 | 190 | 17.0 |

| 3.00-5.00 | 270 | 170 | 17.0 | |

| ME20M | 0.80-3.00 | 250 | 170 | 21.0 |

| 3.00-10.00 | 220 | 140 |

15.0 |

![]()