Hotpress Boron Carbide Sandblasting Nozzles Wet Blast Nozzle For Sandblasting Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad |

| Certification: | ISO |

| Model Number: | wet spray nozzle |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10 pieces |

|---|---|

| Packaging Details: | export package |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Material: | Boron Carbide | Type: | Wet Blast Nozzle |

|---|---|---|---|

| Usage: | Help Workers Decreasing The Prosibility Of Getting Pneumoconiosis | Application: | B4C Ceramic Wet Spray Nozzle For Sandblast Machine |

| Process: | Hotpress | Other Name: | Wet Jet Nozzle |

| High Light: | ceramic sandblast nozzle,carbide sandblast nozzle |

||

Product Description

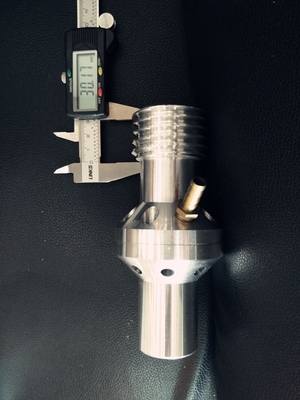

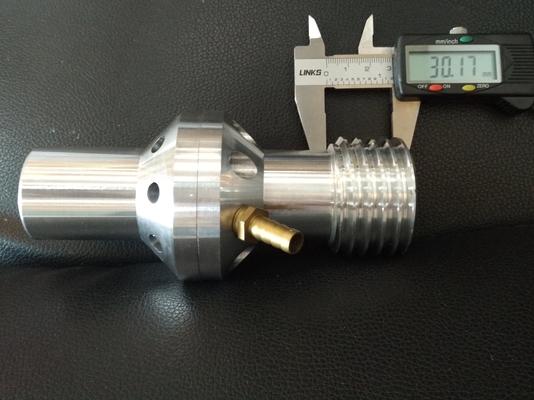

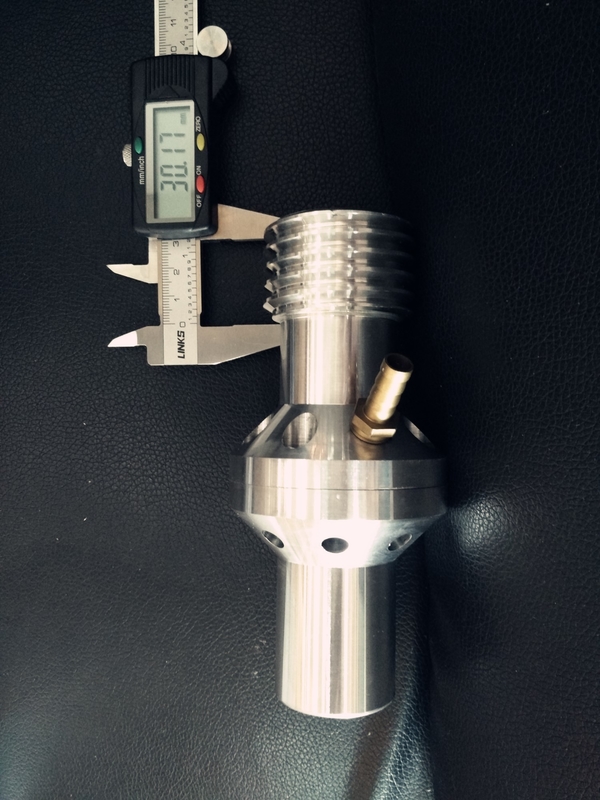

Wet blast Nozzle is a kind of new nozzle that is developed on the foundation of Double Venturi Nozzles.

Wet spray nozzle aborbs water when spraying sands. The water becomes mist, decreasing dusts produced by spraying sands. This process strongly improves the working condistions, which help workers decreasing the prosibility of getting pneumoconiosis. Wet spray nozzle are widely used in steel structure, concrete,marble, granite and ceramic spraying process.

| Series | Inside | Outside | Length |

| HB-WIN-3 | 3/16″ (4.8mm) | 1-1/2″ (38mm) | 140mm |

| HB-WIN-4 | 1/4″ (6.4mm) | 1-1/2″ (38mm) | 150mm |

| HB-WIN-5 | 5/16″(7.9mm) | 1-1/2″ (38mm) | 160mm |

| HB-WIN-6 | 3/8″ (9.5mm) | 1-1/2″ (38mm) | 175mm |

| HB-WIN-7 | 7/16″(11.1mm) | 1-1/2″ (38mm) | 200mm |

| HB-WIN-8 | 1/2″ (12.7mm) | 1-1/2″ (38mm) | 220mm |

Boron carbide nozzle application:

widely used in Industrial production machines such as Sandblasting machines, hydraulic cutters, power plant boilers etc.

Advantage: High temperature resistance, Abrasion-resistance, light unit weight, working life much longer than tradition material.

Specifications:

Density: 2.40-2.65 g/cm3

Elastic modulus: 510 Gpa

Knoop Hardness: 3300

Flexural strength: 400-650 Mpa

Compressive strength: 4100 Mpa

Fracture toughness: 4.5-7.0 Mpa.m1/2

Coefficient of thermal expansion: 4.5x106

Thermal Conductivity: 29 m0k

Maximum permissible service temperature in air: 1500℃

![]()

hotpress boron carbide wet blast nozzle

email: lucky@hbnewmaterial.com