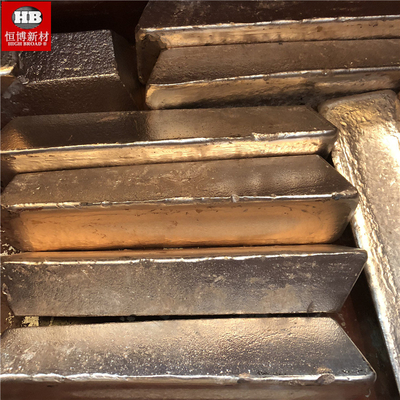

96% Cu 4% Beryllium Copper Alloy CuBe Ingots Shaped

Product Details:

| Place of Origin: | PRC |

| Brand Name: | HB |

| Certification: | ISO, GB |

| Model Number: | OEM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 50kg |

|---|---|

| Price: | USD50/kg |

| Packaging Details: | packed in drums. |

| Delivery Time: | 14 work days |

| Payment Terms: | T/T |

| Supply Ability: | 1t/month |

|

Detail Information |

|||

| Material: | Copper Beryllium | Product Type: | Master Alloy |

|---|---|---|---|

| Composition: | CuBe | Content(percent): | 4% Beryllium |

| Application: | Aerospace And Defense, Automotive, Consumer Electronics, Industrial, Oil And Gas, Telecom And Server | Shape: | Lumps, Ingots |

| High Light: | 4% Beryllium Copper Alloy,Beryllium Copper Alloy CuBe,96% Cu 4% Be Alloy |

||

Product Description

Copper beryllium (CuBe) alloys offer a unique combination of strength, conductivity, hardness and corrosion resistance and are non-magnetic and spark resistant.

Copper based beryllium master alloy which is used to introduce Beryllium into new melts or to replace Beryllium lost through oxidation in remelts.

CuBe materials are successfully used in: Aerospace and Defense, Automotive, Consumer Electronics, Industrial, Oil and Gas, Telecom and Server.

Copper beryllium offers many benefits, including the greatest strength of all copper-based alloys (up to 1,400 MPa / 200,000 psi), conductivity that maintains the flow of electrical and thermal energy, improved miniaturization that allows smaller parts and connectors that have high a repetitive cycle life and can be formed into complex shapes. It has excellent stress relaxation to retain contact force at elevated temperatures and durability that resists wear, corrosion and galling.

- Properties of Beryllium Copper:

Beryllium copper and its range of alloys exhibit a wide range of properties, including:

- High electrical and thermal conductivity

- Non-sparking and non-magnetic characteristics

- High ductility and excellent formability with regards to forming, machining, and metalworking processes

- Higher resistance to corrosion and oxidation than steel

- Higher durability than most copper alloys (resists wear and galling)

- Retention of properties in extremely low or extremely high temperatures

- Suitability for precipitation-hardening operations

- High fatigue strength—also known as endurance strength—making it suitable for heavy cyclic load applications

- Applications/Industries Served by Beryllium Copper:

- Beryllium copper finds use in several different industries due to its unique properties. For instance, its non-sparking characteristics make it highly suitable for applications within the oil and gas industry, such as for oil rig components or mining tools.

- Other industrial applications which employ beryllium copper include:

- Computers and electronics

- Fabrication of non-sparking tools

- Fasteners

- Telecommunication products

- Valve seats and cryogenics

- Injection mold design

- Musical instruments (percussion, strings, etc.)

Chris Huang

China Hunan High Broad New Material Co.Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85713359 Fax:+86-731-85716569

Mobile/Whatsapp: +86-185-0731-5452

chris@hbnewmaterial.com chrishuang@vip.qq.com