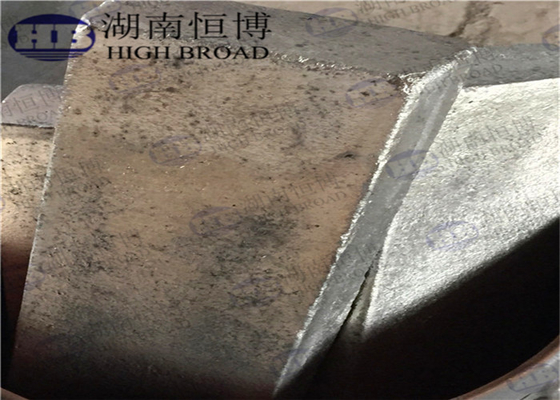

Grain refined Magnesium Manganese alloy ingot , MgMn master alloy

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad New Material |

| Certification: | Aviation standard |

| Model Number: | MgAl |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 kgs |

|---|---|

| Price: | negotiable |

| Packaging Details: | in steel drums |

| Delivery Time: | 1 FCL: 14 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union,Paypal |

| Supply Ability: | 30 mt/month |

|

Detail Information |

|||

| Content: | Manganese 2%, 3%, 5% , 10% | Chemical: | Magnesium , Manganese |

|---|---|---|---|

| Standard: | HB7264-96 | Application: | Grain Refine |

| Improve: | Elongation | Composition: | MgMn MgCa MgY MgN43d MgSc MgSr MgZr MgLa WE |

| High Light: | sacrificial anode protection,magnesium aluminum alloy |

||

Product Description

Grain refined Magnesium Manganese alloy ingot , MgMn master alloy

Standard: HB7264-96

| Grade | Chemicals % | |||||

| Alloys | Impurities | |||||

| Mn | Mg | Fe | Si | Cu | Ni | |

| Mg-Mn10% | 10.15 | balance | 0.0062 | 0.01 | 0.0041 | 0.0052 |

Here we can supply:

MgMn,MgCa,NiMg, MgDy,MgEr ,MgZr,MgY,MgSc, MgCe,MgLa,MgGd,MgNd,etc.

High Strength magnesium alloy: ZK60,ZM6,ZE41A , WE43,WE54,WE94,

Application:

improve magnesium Mechanical properties

Other information for your reference:

Mg-Zn-RE-Zr. Binary Mg-Zn alloys show inferior mechanical properties and castability, but the addition of zirconium for grain refinement and rare earth (RE) elements to reduce microporosity, led to the development of alloys such as EZ33 and ZE41. These alloys have been used widely as sand castings in the T5 condition (cooled and artificially aged) for applications involving exposure to moderately elevated temperature (up to ca. 200 °C). The ZE63 alloy is a high-strength variant in which solution heat treatment in a hydrogen atmosphere is employed to remove some of the embrittling Mg-Zn-RE grain boundary phases. In extrusion, microporosity is of less concern and Mg-Zn-Zr alloys are used without RE additions.

Mg-Ag-RE-Zr. Addition of silver and neodymium-rich misch metal, in addition to zirconium, promotes age hardening efficiently when the alloy is given a full T6 treatment (solution heat-treated and artificially aged). The precipitates formed are relatively stable; the alloy shows high mechanical strength and good creep properties at temperatures approaching 250 °C.

Mg-Y-RE-Zr. The most recently developed alloy system for high-temperature application is based upon additions of yttrium and neodymium-rich misch metal. This alloy system was developed to meet the ever-increasing high-temperature performa

*What is Master alloy?

1. Hardeners

Change composition of metal alloys

2.Grain Refiners

Control the structure and dispersion of individual crystals in metals

Improved mechanical strength and soundness of the casting

3.Modifiers

Change micro-structural properties of metal

Increase metal strength, toughness, ductility, and resultant machinability.

* I should choose which product ?

Tell us your target material performance, we will provide accordingly master alloy or design a new type alloy especially for you !

*I don’t know how to use your products ?

Our professional technical engineer will provide detailed guidance to you.

*I have alloying production difficulties !

We will provide professional technical solution to help you overcome problems!

Company Belief:

Continuous Innovation

Our Spirit:

Sincerity, Unity , Dedicated, Hardworing

Our Mission:

Provide most advanced products & most professional technical solution.

![]()

![]()

Contact me for more details:

Vivian Jiang(Ms.)

International Marketing & Sales Department Manager

-----------------------------------------------

China Hunan High Broad New Material Co.Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705 Fax:+86-731-85716569

Mobile/Whatsapp: +86-139-7488-3816

Email: vivian@hbnewmaterial.com ,metal@vip.163.com

Skype: vivian.jjy