MgLa5 MgLa25 Magnesium Master Alloy Magnesium Lanthanum Master Alloy Ingot

Product Details:

| Place of Origin: | China |

| Brand Name: | High Broad/OEM |

| Certification: | GB,ISO |

| Model Number: | MgLa |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1kg for MgLa5 MgLa25 Magnesium Lanthanum master alloy ingot ,Magnesium based master alloy |

|---|---|

| Price: | negotiable |

| Packaging Details: | In Vacuum plastic bag and then in steel drums |

| Delivery Time: | 2days for 1ton |

| Payment Terms: | D/P, L/C, T/T, Western Union, MoneyGram,Paypal etc |

| Supply Ability: | 500mt per month |

|

Detail Information |

|||

| Product Name: | MgLa5 MgLa25 Magnesium Lanthanum Master Alloy Ingot ,Magnesium Based Master Alloy | Application: | Improve Castability,creep Resistance And Tensile Strenth In High Temperature And Anticorrosion. |

|---|---|---|---|

| Chemical: | Magnesium Lanthanum | Content: | MgLa 5,25% |

| Chemical Composition: | La;Fe;Si;Cu;AI;Ni;Mn;Mg | Commodity: | MgLa Alloy Ingot |

| Shape: | Rectangle,Square, Round Bar | Belongs: | Rare Earth Alloy |

| Usage: | Used For Degassing,de-impurity,edulcoration And Refining Gain | Process: | Semi-Casting&Hot Rolling |

| High Light: | sacrificial anode protection,magnesium aluminum alloy |

||

Product Description

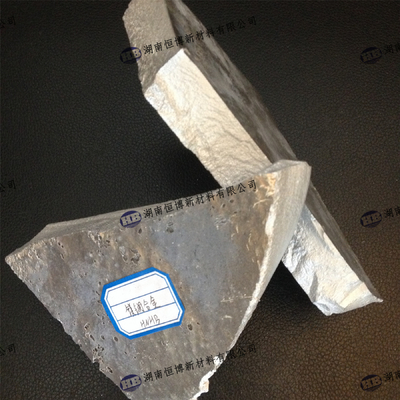

MgLa5 MgLa25 Magnesium Lanthanum master alloy ingot ,Magnesium based master alloy

1.Product information

1.Used for degassing,de-impurity,edulcoration and refining gain

2.Used for solid solution strengthening

3.Improving the creep resistance

![]()

![]()

| Product name | Product model | Main element content | Impurity Content (≤%) | Mg | ||||

| Fe | Si | Cu | AL | Ni | ||||

| Mg-La master alloy | ||||||||

| MgLa5 | La5±0.5% | 0.35 | 0.15 | 0.1 | 0.05 | 0.01 | Balance | |

| MgLa25 | La25±1% | 0.35 | 0.15 | 0.1 | 0.05 | 0.01 |

||

2.Other information:

1.The shape is ingot or as customer's request.

2.Key elements and impurity content are in line with relevant national or industry standards,also available upon request.

3.Directions for use

According to the customer request to add rare earth alloy. Removing Packaging shrink film first and preheat to 200 ℃. After adding all alloy, raise temperature to 820℃±50℃ and stirring.

Note: Please choose earth special flux as refining flux .

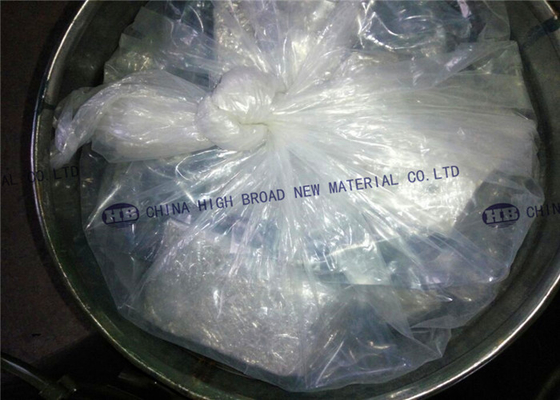

4.Packing

SEAWORTHY PACKING, VACUUM PACKING, PLASTIC FILM PACKED AND PUT INTO IRON DRUM WITH VACUUM. ALSO AS CLIENTS' REQUIREMENT.

Magnesium basis master alloy: MgCa,MgMn,MgY,MgSr,MgZr,MgGd,MgSc etc.

Aluminum basis master alloy: AlTi,AlCu,AlV,AlSr,AlZr,AlMn,AlSc etc.

6.Company Principle:

Our Belief: Continuous Innovation.

Our Spirit: Sincerity, Unity, Dedicated, Hardworking.

Our Mission: Provide most advanced products & most professional technical solution.

7.Company Brief Introduction:

China Hunan High Broad was established in year 2006. We devote ourselves to researching, developing, producing and selling of New Materials. The sales office is located in Changsha ,China. The manufacturing base is located in Henan and Shanxi province, which with over 5000mt annual capacity of Magnesium base master alloy, Magnesium anodes, Aluminum anodes, Zinc anodes, Aluminum base master alloy, Rare earth master alloy, Zinc base master alloy, magnesium alloy billet,advanced Industrial Ceramics, and other new materials, which are widely applied in high-tech field such as aerospace, machine manufacturing, electrommunication ,etc. Our products are accepted and recognized by clients worldwide including Europe, America, East Asia etc..

Our technical team have leading design and R&D ability, we can supply high quality & stable products, and also provide the technical solution during your producing and processing.

We took a part in many R&D projects in colleges and universities, and started strategic cooperation with many companies in China and overseas.

Believe we are the top choose to become your best partner.

8.Contact us for more information:

Jane Hu(Ms)

China Hunan High Broad New Material Co., Ltd.

70 Chezhan North Road,Changsha, China 410100

Tel:+86-731-85717705

Mobile/Whatsapp: +86-139-7515-2932